| Application | Solid particle pipeline | Place of Origin | China |

|---|---|---|---|

| Power | Electric | Customized support | OEM, ODM |

| Warranty | 3 years | Model Number | 2"-24" |

| Temperature of Media | Low Temperature, Normal Temperature | Media | sewage |

| Connection | Flange Ends | Color | Customized Color |

| Packing | Wooden Case | Seat | EPDM NBR |

| Applicable media | Weak Acid-base Medium |

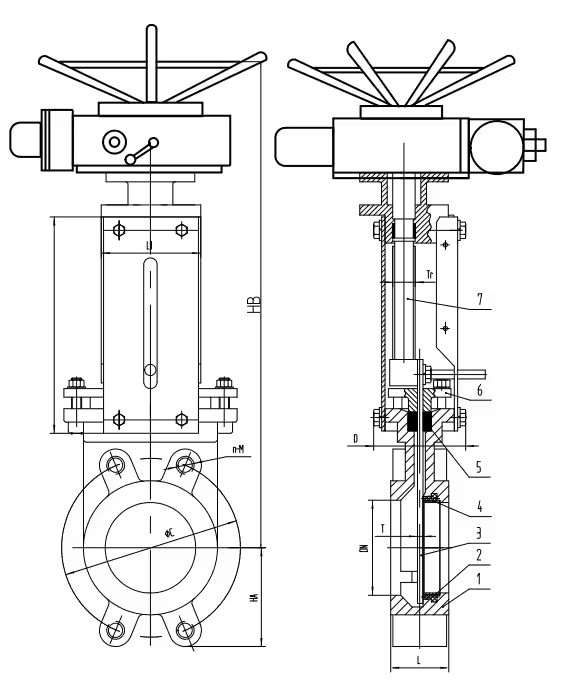

Product Overview

The electric knife gate slurry valve is designed for efficient flow control in slurry applications. Its ductile iron body provides excellent strength and durability, while the bidirectional design ensures flexibility in operation.

Features

- Ductile iron construction for enhanced durability

- Electric actuator for precise control

- Bidirectional flow capability

- Designed for handling abrasive slurries

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Electric Knife Gate Slurry Valve |

| Body Material | Ductile Iron |

| Operation | Electric |

| Connection Type | Flanged |

| Flange Standard | ANSI B16.5 / DIN / JIS |

| Pressure Rating | PN10 / PN16 / Class 150 |

| Temperature Range | -10°C to 120°C (14°F to 248°F) |

| Size Range | DN50 to DN600 |

| Seal Material | EPDM / PTFE / Metal |

| Actuator Voltage | 24V/110V/220V AC/DC |

| Leakage Rate | Zero leakage (Metal to Metal) |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Verify flange compatibility.

Mounting: Align the valve with the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts in a criss-cross pattern for even pressure.

Electrical Connection: Connect the electric actuator to the power supply as per the wiring diagram provided. Ensure proper grounding.

Inspection: Verify smooth operation by manually testing the actuator. Ensure there are no obstructions.

Operation Guidelines

- Opening/Closing: Use the control panel or remote system to operate the actuator for opening and closing the valve.

- Flow Control: Adjust settings on the actuator for precise flow regulation.

Maintenance

- Regular Inspection: Check for signs of wear or damage. Ensure the actuator and valve components are in good condition.

- Seal Replacement: Inspect seals periodically and replace if necessary to maintain zero leakage.

- Cleaning: Keep the valve and actuator clean and free from external contaminants.

Safety Precautions

- Always depressurize the system before performing maintenance.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Electrical issue or obstruction | Check power supply and clear obstruction |

| Leakage | Worn or damaged seal | Replace the seal |

| Actuator malfunction | Electrical fault | Inspect wiring and connections |

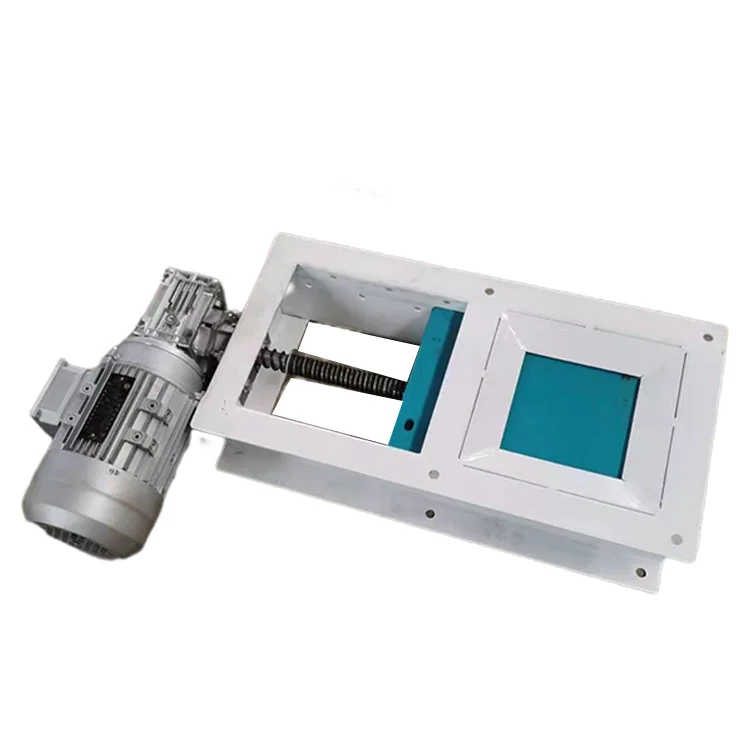

Product Show