| Application | General | Place of Origin | ShenZhen, China |

|---|---|---|---|

| Power | Electric | Customized support | OEM, ODM, OBM |

| Warranty | 1 years | Model Number | Electric knife gate valve |

| Temperature of Media | High Temperature, Low Temperature, Medium Temperature, Normal Temperature | Brand Name | COVNA |

| Media | Base | Product name | Motorized knife gate valve |

| Body material | Stainless Steel, WCB, Ductile iron | Pressure | 200psi/PN16 |

| Standard or Nonstandard | ANSI BS DIN JIS | Medium | Water Oil Gas |

| Connection | Flanged | Working medium | Air Water Oil |

| Size | 2''~12'' |

1. Introduction

The Stainless Steel Motor-Driven Electric Knife Gate Valve is designed for automated control of fluid flow in various industrial applications. This valve features a robust knife gate design and an electric actuator for efficient and reliable operation. Made from stainless steel, it offers excellent corrosion resistance and durability, making it suitable for harsh environments.

2. Features

- Material: Stainless Steel body and gate (SS304/SS316).

- Design: Knife gate design to handle slurry, viscous, and abrasive fluids.

- Seal: Resilient or metal-to-metal seal options for tight closure.

- Actuation: Electric actuator for automated operation.

- Connection: Flanged, wafer, or lugged ends for versatile installation.

- Pressure Rating: Typically PN10 or PN16.

- Standards: Manufactured according to industry standards (e.g., ISO, API).

3. Applications

- Sewage treatment plants.

- Mining industry.

- Pulp and paper industry.

- Chemical processing.

- Power generation.

- Food and beverage industry.

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | Various sizes available |

| Body Material | Stainless Steel (SS304/SS316) |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) or Metal-to-Metal |

| Pressure Rating | PN10, PN16 |

| Temperature Range | -10°C to 200°C (14°F to 392°F) |

| Connection Type | Flanged, Wafer, Lugged |

| Face-to-Face Dimension | According to ISO 5752 or API 609 |

| Media | Various fluids, including corrosive and abrasive |

| Operating Voltage | Typically 220V/380V AC |

| Actuation | Electric Actuator |

| Leakage Rate | Zero leakage (resilient seal) |

| Testing Standard | API 598 |

5. Installation Instructions

5.1 Preparation

- Ensure the pipeline is clean and free of debris.

- Verify that the valve specifications match the application requirements.

- Check the electric actuator for proper configuration and voltage compatibility.

5.2 Alignment

- Align the valve with the pipeline flanges.

- Ensure proper alignment to avoid stress on the valve body and flanges.

5.3 Bolting

- Secure the valve using appropriate bolts and nuts.

- Tighten bolts evenly in a crisscross pattern to ensure a proper seal.

5.4 Electrical Connection

- Connect the electric actuator to the power supply according to the manufacturer's wiring diagram.

- Ensure all electrical connections are secure and properly insulated.

5.5 Testing

- Test the valve for proper operation using the electric actuator.

- Check for leaks and ensure the valve opens and closes smoothly.

6. Maintenance

6.1 Regular Inspection

- Periodically inspect the valve and actuator for signs of wear or damage.

- Check the gate, seals, and stem for any abnormalities.

6.2 Seal Replacement

- Replace the seals if leakage is detected.

- Use compatible seal materials for the specific media and operating conditions.

6.3 Actuator Maintenance

- Follow the actuator manufacturer's maintenance guidelines.

- Ensure the actuator operates smoothly and is free from debris.

6.4 Gate Inspection

- Inspect the gate for wear and replace if necessary.

- Ensure the gate moves freely without obstruction.

7. Safety Precautions

- Ensure the pipeline is depressurized before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

- Ensure all electrical connections are de-energized before maintenance.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Actuator not responding | Electrical issue or actuator fault | Check electrical connections and actuator status |

| Difficulty in manual operation | Debris or damage in the stem or gate | Clean and inspect the stem and gate |

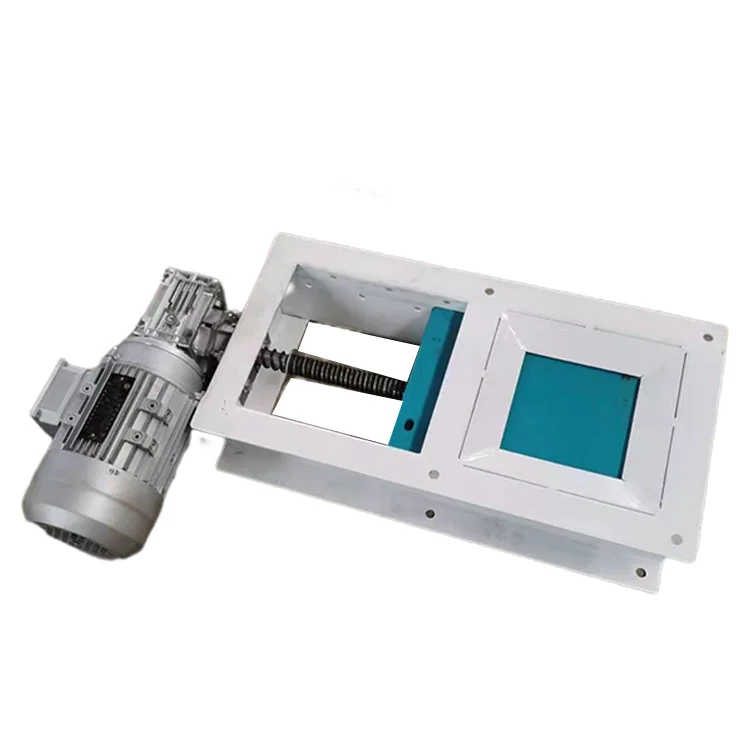

Product Show

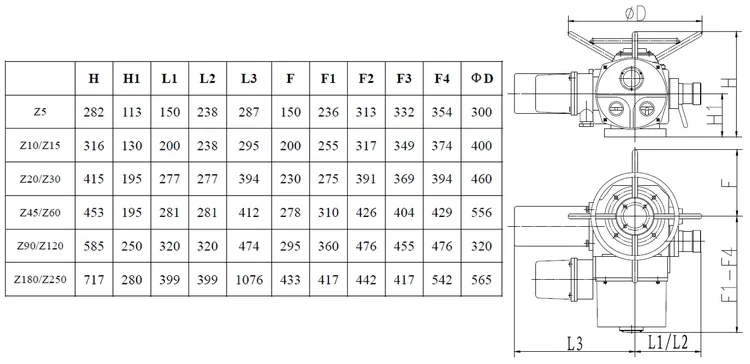

| Size | L | L1 | H | H1 | F1(normal) | F2(smart) | Φ D |

| Z5-15 | 382 | 228 | 233 | 87 | 150 | 203 | 300 |

| Z20-35 | 435 | 278 | 248 | 90 | 157 | 210 | 350 |

| Z45-60 | 640 | 410 | 325 | 116 | 268 | 380 | 420 |

| Z90-120 | 830 | 540 | 450 | 200 | 685 | 510 | 550 |

| Z180-250 | 870 | 565 | 600 | 250 | 740 | 535 | 320 |

| Z350-500 | 1170 | 770 | 710 | 280 | 840 | 450 | 570 |

COVNA Valve Co., Ltd.

COVNA is one of the top manufacturers of quarter turn actuators and actuated valve products in China with 24 years experience. All COVNA products are designed and manufactured by experienced engineers to provide safe and reliable valves, actuators and solutions. COVNA aims to provide our customers the best quality products with the most competitive pricing, on-time delivery and full warranty service.

QUICK QUOTE