| Application | General | Place of Origin | Shenzhen, China |

|---|---|---|---|

| Power | Electric | Customized support | OEM, ODM, OBM |

| Model Number | PZ973X-16C | Brand Name | KAILIWEI |

| Valve performance characteristics | Round single valve plate type | Connection method | flange |

| Operating temperature | -25℃~325℃ | Actuator performance characteristics | Ordinary switch type |

| working medium | sewage, dust | Nominal diameter | 200(mm) |

| Nominal pressure | 1.0Mpa | sealing material | alloy steel |

| Body material | Body material |

1. Introduction

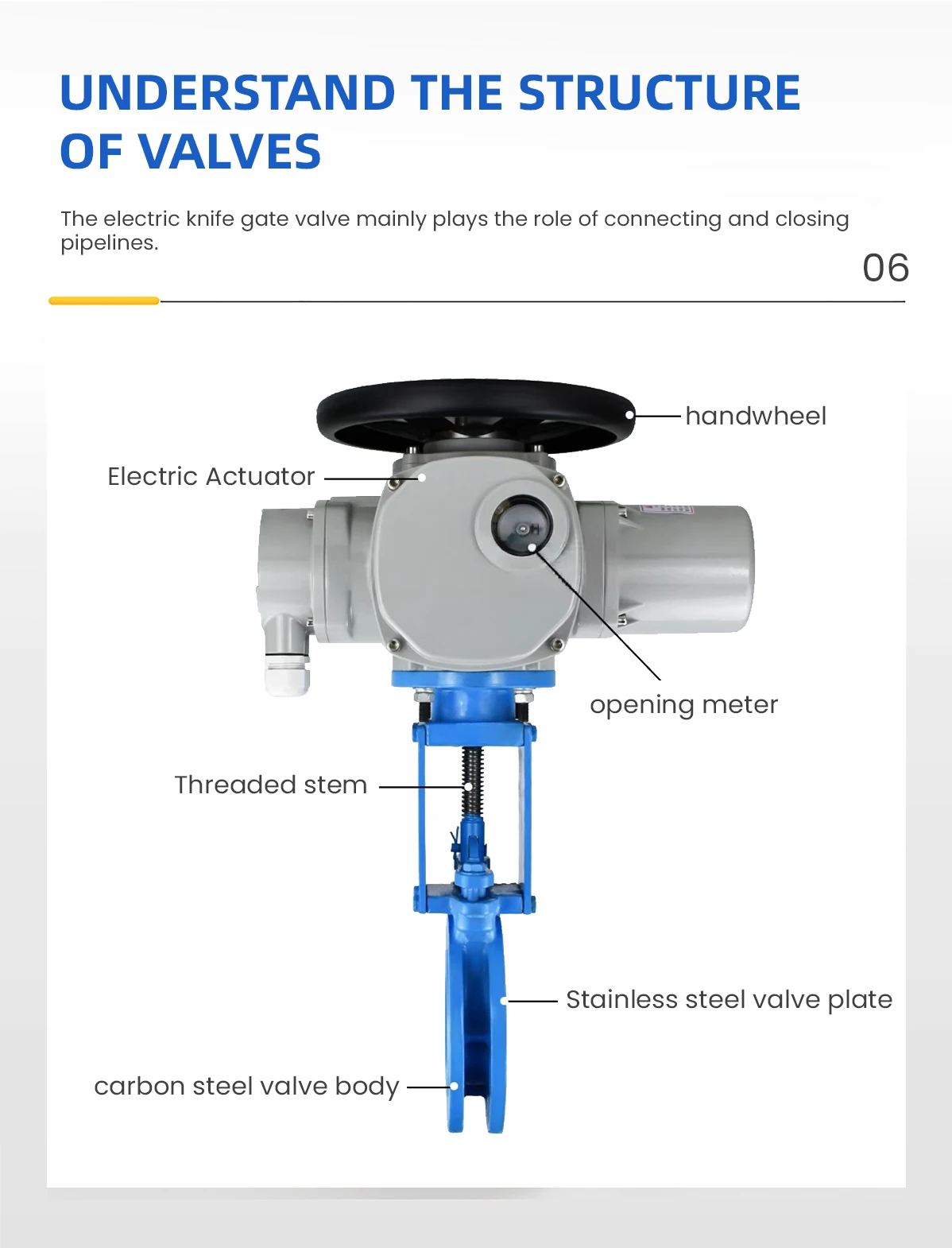

The PZ973X-16C Electric Actuator Knife Type Stainless Steel Gate Valve is designed for precise and automated control of fluid flow in various industrial applications. This valve features a robust stainless steel knife gate and an electric actuator for efficient and reliable operation. It is suitable for handling slurry, viscous, and abrasive fluids.

2. Features

- Material: Stainless Steel body and gate (SS304/SS316).

- Design: Knife gate design to handle slurry, viscous, and abrasive fluids.

- Seal: Resilient or metal-to-metal seal options for tight closure.

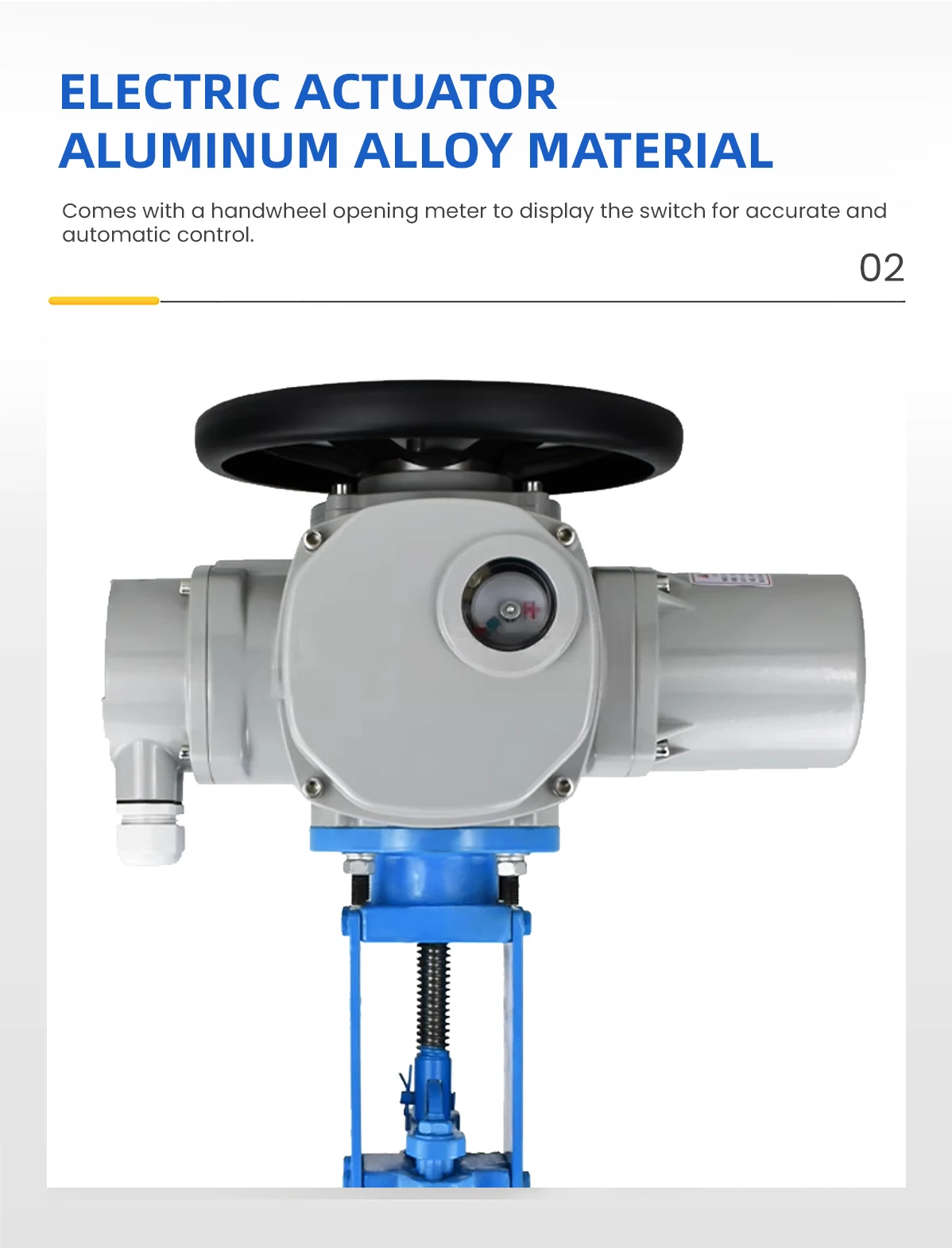

- Actuation: Electric actuator for automated operation.

- Connection: Flanged, wafer, or lugged ends for versatile installation.

- Pressure Rating: PN16 (16 bar).

- Standards: Manufactured according to industry standards (e.g., ISO, API).

3. Applications

- Mining industry.

- Wastewater treatment plants.

- Pulp and paper industry.

- Chemical processing.

- Power generation.

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | Various sizes available |

| Body Material | Stainless Steel (SS304/SS316) |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) or Metal-to-Metal |

| Pressure Rating | PN16 (16 bar) |

| Temperature Range | -10°C to 200°C (14°F to 392°F) |

| Connection Type | Flanged, Wafer, Lugged |

| Face-to-Face Dimension | According to ISO 5752 or API 609 |

| Media | Slurry, abrasive and viscous fluids |

| Operating Voltage | Typically 220V/380V AC |

| Actuation | Electric Actuator |

| Leakage Rate | Zero leakage (resilient seal) |

| Testing Standard | API 598 |

5. Installation Instructions

5.1 Preparation

- Ensure the pipeline is clean and free of debris.

- Verify that the valve specifications match the application requirements.

- Check the electric actuator for proper configuration and voltage compatibility.

5.2 Alignment

- Align the valve with the pipeline flanges.

- Ensure proper alignment to avoid stress on the valve body and flanges.

5.3 Bolting

- Secure the valve using appropriate bolts and nuts.

- Tighten bolts evenly in a crisscross pattern to ensure a proper seal.

5.4 Electrical Connection

- Connect the electric actuator to the power supply according to the manufacturer's wiring diagram.

- Ensure all electrical connections are secure and properly insulated.

5.5 Testing

- Test the valve for proper operation using the electric actuator.

- Check for leaks and ensure the valve opens and closes smoothly.

6. Maintenance

6.1 Regular Inspection

- Periodically inspect the valve and actuator for signs of wear or damage.

- Check the gate, seals, and stem for any abnormalities.

6.2 Seal Replacement

- Replace the seals if leakage is detected.

- Use compatible seal materials for the specific media and operating conditions.

6.3 Actuator Maintenance

- Follow the actuator manufacturer's maintenance guidelines.

- Ensure the actuator operates smoothly and is free from debris.

6.4 Gate Inspection

- Inspect the gate for wear and replace if necessary.

- Ensure the gate moves freely without obstruction.

7. Safety Precautions

- Ensure the pipeline is depressurized before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

- Ensure all electrical connections are de-energized before maintenance.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Actuator not responding | Electrical issue or actuator fault | Check electrical connections and actuator status |

| Difficulty in manual operation | Debris or damage in the stem or gate | Clean and inspect the stem and gate |

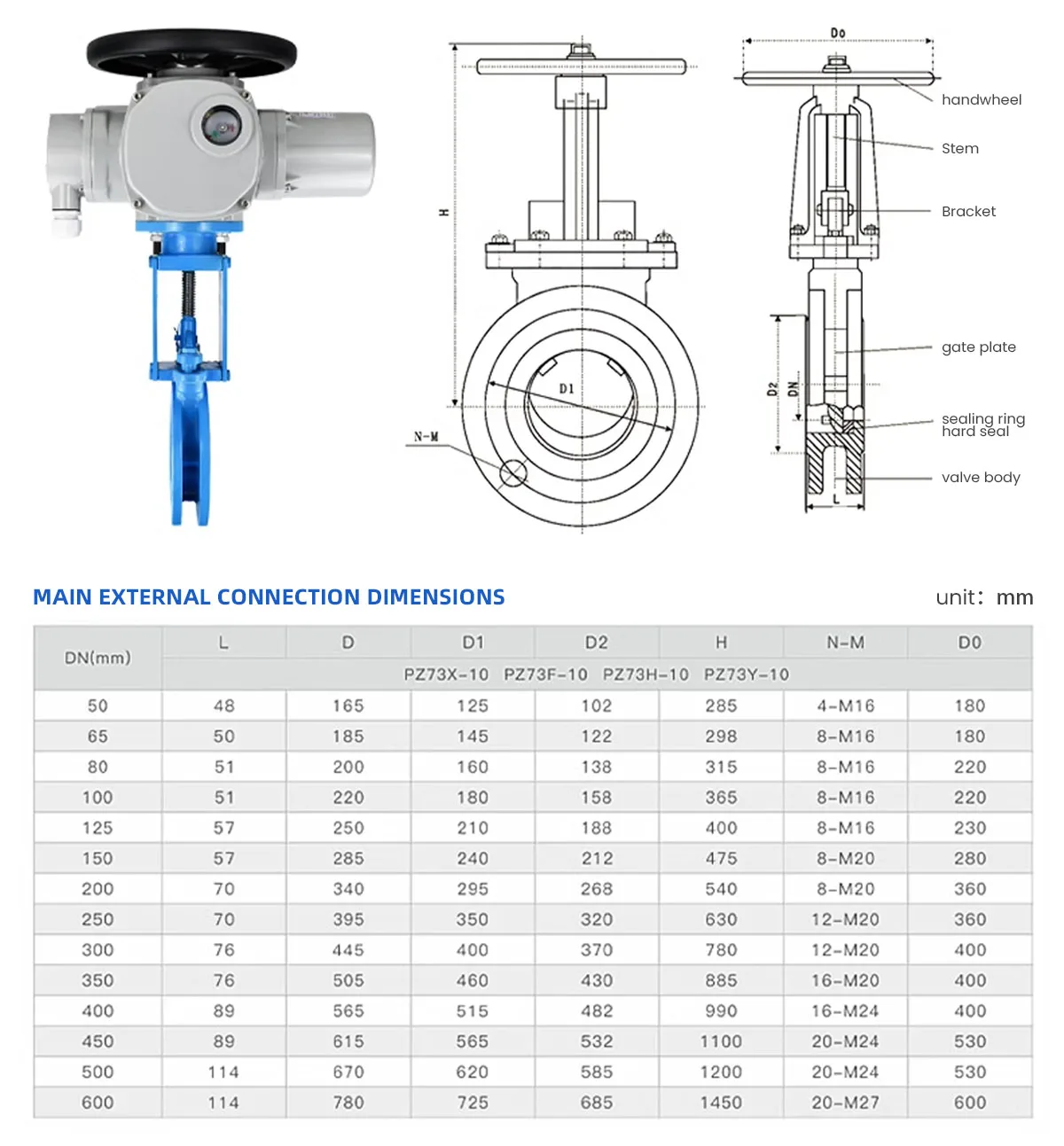

| Name | Electric knife gate valve |

| Model | PZ973X-16C/P |

| Power supply voltage | 220v |

| Valve body material | stainless steel/carbon steel |

| Valve plate material | stainless steel/carbon steel |

| Sealing form | hard seal/soft seal |

| Connection method | clamping |

| Working type | switch type/adjusting type |

| Applicable temperature | hard seal ≤ 425 ℃ / soft seal ≤ 80 ℃ |