| Application | Slurry | Place of Origin | China |

|---|---|---|---|

| Power | Pneumatic | Customized support | OEM, ODM |

| Warranty | 3 years | Model Number | DN50-DN600 |

| Temperature of Media | Low Temperature, Normal Temperature | Media | Water and slurry |

| Type | Gate Valves | Product name | knife gate valve |

| Body material | Ductile Iron/Cast Iron GGG50 | Color | Customized Color |

| Seat | EPDM NBR | Connection | Flange Ends |

| Disc Material | 316 CF8M |

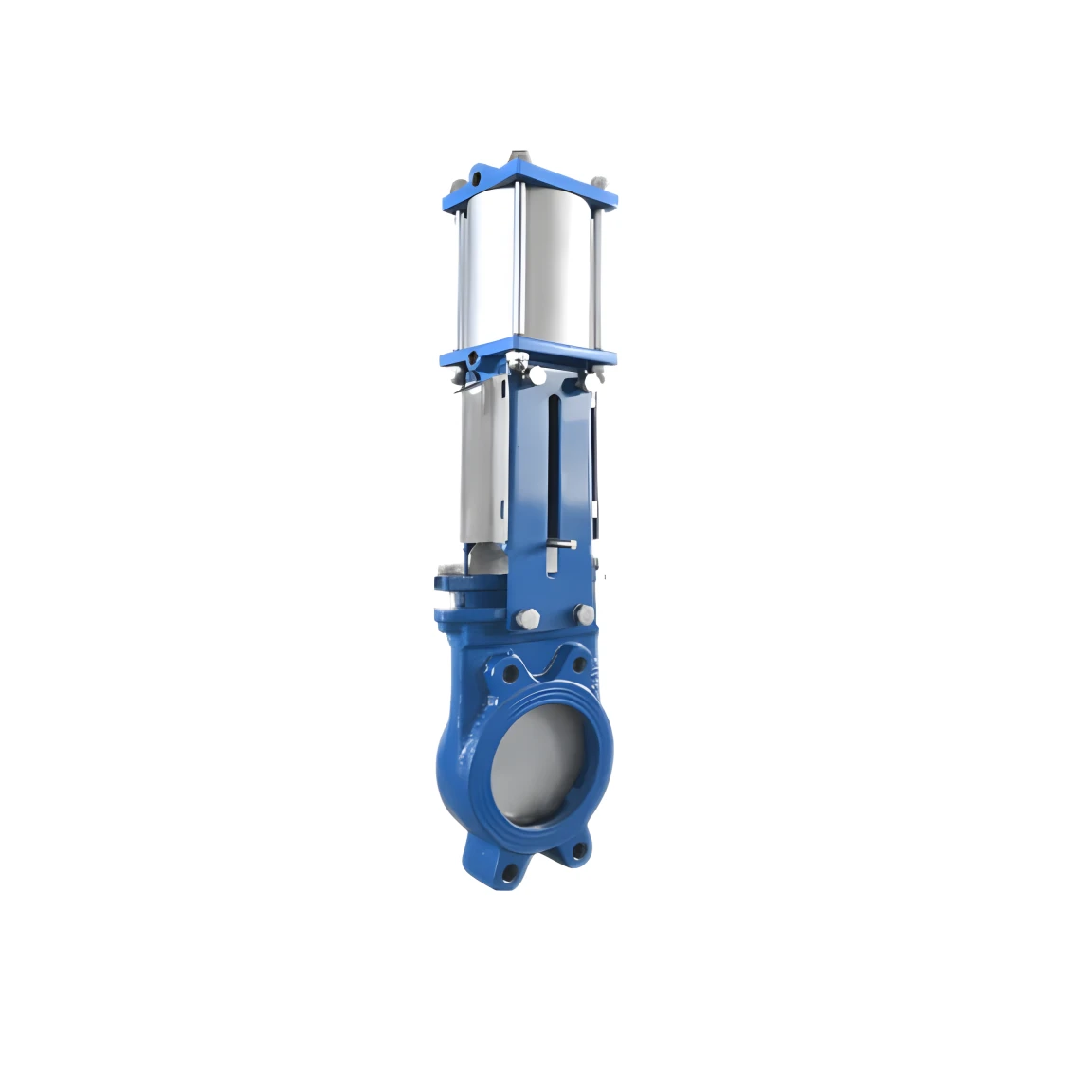

Product Overview

The Pneumatic Control Valve, specifically a 2-inch Ductile Iron Soft Sealed One-Way Knife Gate Valve, is designed for precise and reliable flow control in slurry applications. The valve is ideal for industries such as mining, wastewater treatment, and pulp and paper, where handling abrasive and viscous fluids is required. The pneumatic actuator allows for automated operation, enhancing control and efficiency.

Features

- Material: High-strength ductile iron body for durability and resistance to wear.

- Design: One-way knife gate design to cut through slurry and viscous media effectively.

- Actuation: Pneumatic actuator for automated and remote operation.

- Sealing: Soft seal for excellent leakage prevention.

- Maintenance: Easy to maintain with replaceable components.

Applications

- Mining: Ideal for handling abrasive slurry.

- Wastewater Treatment: Effective in managing sludge and wastewater.

- Pulp and Paper Industry: Suitable for handling pulp slurry and paper stock.

- Chemical Industry: Handles various chemicals with high efficiency.

Technical Parameters

| Parameter | Specification |

|---|---|

| Model | PNKGV-DI-SS-2 |

| Body Material | Ductile Iron |

| Nominal Pressure | 1.0 MPa (10 bar) |

| Nominal Diameter | 2-inch (DN50) |

| Connection Type | Wafer |

| Actuator Type | Pneumatic |

| Sealing Material | EPDM, NBR, PTFE |

| Operating Temperature | -10°C to 80°C |

| Medium | Slurry, pulp, wastewater, chemicals |

| End Connection | ANSI B16.5, DIN, JIS |

| Air Supply Pressure | 0.4 - 0.7 MPa |

| Control Signal | 4-20mA, 0-10V |

| Protection Class | IP65 |

Installation and Operation

Installation:

- Ensure the pipeline is clean and free from debris before installation.

- Position the valve between the pipeline flanges and align the bolt holes.

- Insert and tighten the bolts evenly to secure the valve in place.

- Connect the pneumatic actuator to the air supply and control system as per the wiring diagram provided.

Operation:

- The valve can be operated remotely via the control system.

- For manual operation in case of actuator failure, use the manual override feature on the actuator.

- Regularly check the valve and actuator for any signs of wear or damage.

Maintenance:

- Periodically inspect the sealing surfaces and replace seals if necessary.

- Lubricate the moving parts of the actuator as per the manufacturer's recommendations.

- Ensure the pneumatic connections are secure and free from leaks.

Safety Precautions

- Always depressurize the pipeline before performing any maintenance.

- Disconnect the air supply to the actuator before servicing.

- Use appropriate personal protective equipment (PPE) when handling the valve and during maintenance.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Air supply failure | Check and restore air supply |

| Leakage | Worn or damaged seals | Replace seals |

| Actuator malfunction | Pneumatic fault or leakage | Inspect and repair or replace actuator |

| No response to control signal | Faulty wiring or control system | Verify wiring and control system integrity |

Product Showcase