| Application | General | Place of Origin | ShenZhen, China |

|---|---|---|---|

| Power | Pneumatic | Customized support | OEM, ODM |

| Warranty | 3 years | Model Number | HKJ-240028 |

| Temperature of Media | High Temperature, Low Temperature, Medium Temperature, Normal Temperature | Brand Name | YM |

| Media | Water Oil Gas | Standard or Nonstandard | Standad |

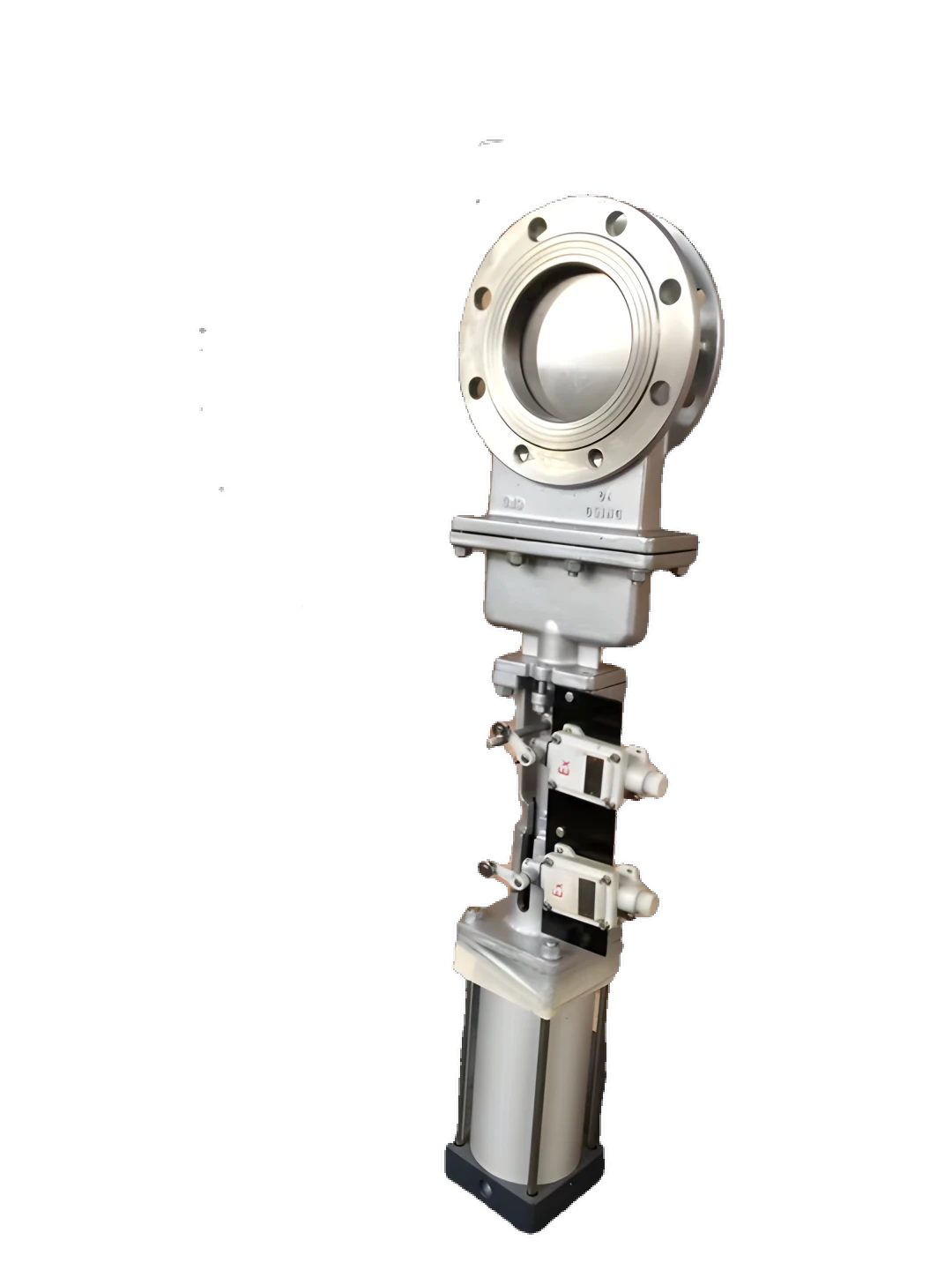

Product Overview

This valve is engineered for robust performance in demanding environments, featuring a pneumatic actuator for efficient automation.

Features

- Pneumatic actuator for automated control

- Carbon steel construction for strength and durability

- Flanged connection for secure installation

- Designed for handling various fluids and slurries

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Knife Gate Valve |

| Body Material | Carbon Steel |

| Operation | Pneumatic |

| Connection Type | Flanged |

| Pressure Rating | PN10/16 |

| Temperature Range | -20°C to 120°C (-4°F to 248°F) |

| Size | As specified |

| Seal Material | Reinforced Rubber or Metal |

| Leakage Rate | Minimal leakage |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Verify flange compatibility.

Mounting: Align the valve with the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts in a criss-cross pattern for even pressure distribution.

Pneumatic Connection: Connect the pneumatic actuator to the air supply according to the manufacturer's specifications. Ensure all connections are secure and leak-free.

Inspection: Test the actuator to ensure smooth operation and check for any obstructions in the valve.

Operation Guidelines

- Opening/Closing: Use the control system to operate the pneumatic actuator for opening and closing the valve.

- Flow Control: Ensure the valve is fully open or closed to prevent partial obstruction and ensure optimal flow control.

Maintenance

- Regular Inspection: Perform regular inspections for signs of wear or damage. Ensure the actuator and valve components are in good condition.

- Seal Maintenance: Inspect seals periodically and replace if necessary to maintain tight sealing and prevent leakage.

- Cleaning: Keep the valve and actuator clean and free from external contaminants to ensure smooth operation.

Safety Precautions

- Always disconnect the air supply before performing any maintenance or inspection.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Air supply issue or obstruction | Check air supply and clear obstruction |

| Leakage | Worn or damaged seal | Replace the seal |

| Actuator malfunction | Pneumatic fault | Inspect connections and air lines |

Product Show