| Application | General | Place of Origin | ShenZhen, China |

|---|---|---|---|

| Power | Pneumatic | Customized support | OEM, ODM |

| Warranty | 1 year | Model Number | DN150 |

| Temperature of Media | Medium Temperature | Brand Name | Guanyu |

| Media | powder | Standard or Nonstandard | Standard |

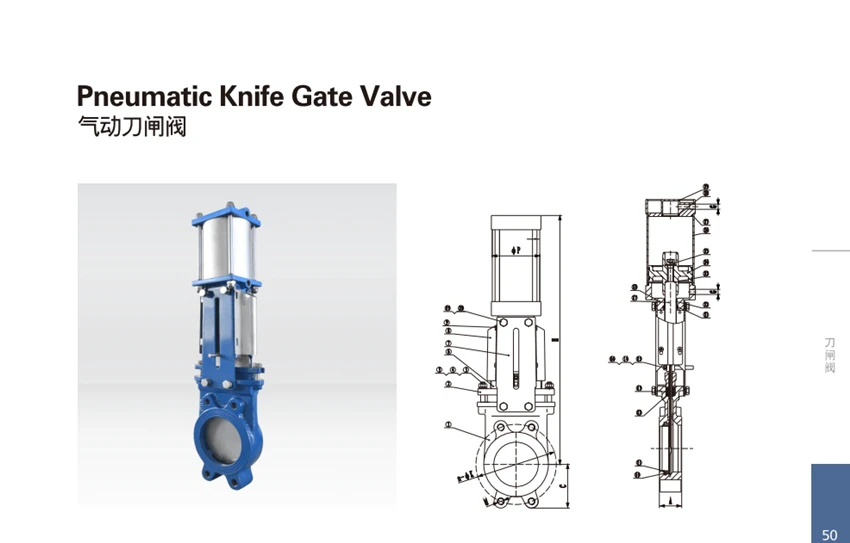

| Product name | Pneumatic Knife Gate Valve | Size | DN150 |

| Body material | ss304 | Gate material | ss304/316 |

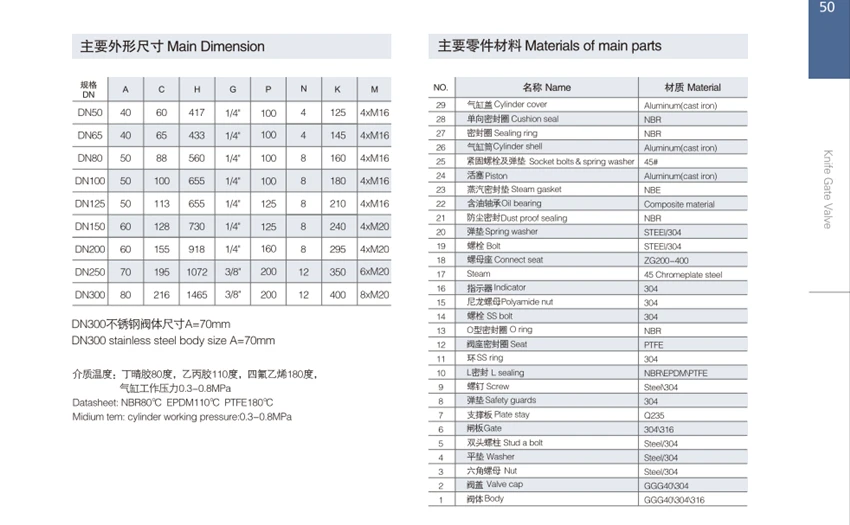

| Cylinder working pressure | 0.3---0.8Mpa | Certificate | ISO9001 |

| Color | Blue | Medium | liquid,powder,corrosive liquid and so on. |

| Seal Material | NBR/EPDM |

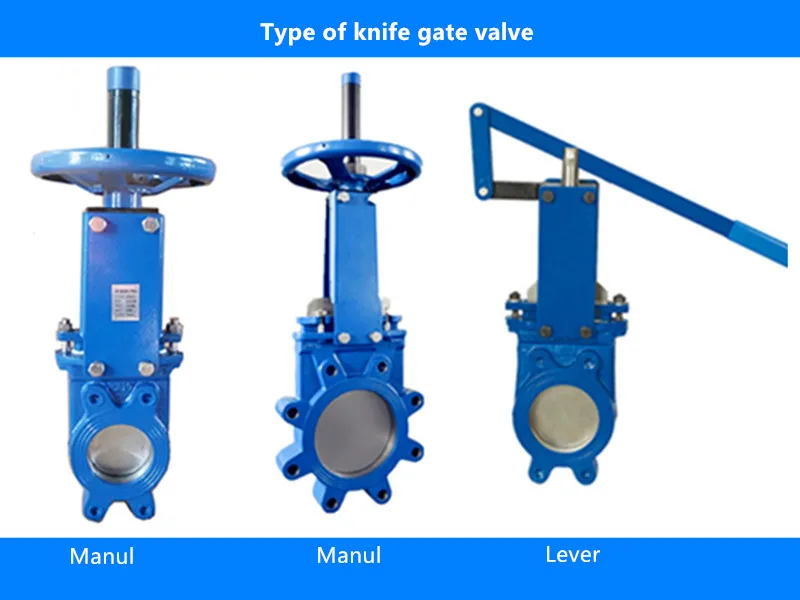

Product Overview

This valve is ideal for slurry handling, featuring a pneumatic actuator for efficient and automated operation.

Features

- Pneumatic actuator for automated control

- Ductile iron construction for durability

- Wafer type design for easy installation

- Suitable for slurry and abrasive materials

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Knife Gate Valve |

| Body Material | Ductile Iron |

| Operation | Pneumatic |

| Connection Type | Wafer |

| Pressure Rating | PN10 |

| Temperature Range | -10°C to 80°C (14°F to 176°F) |

| Size | 6 Inch (DN150) |

| Seal Material | Reinforced Rubber or Metal |

| Leakage Rate | Minimal leakage |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Verify compatibility with the wafer type connection.

Mounting: Position the valve between the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts evenly in a criss-cross pattern.

Pneumatic Connection: Connect the pneumatic actuator to the air supply according to the manufacturer's specifications.

Inspection: Test the actuator to ensure smooth operation and check for any obstructions.

Operation Guidelines

- Opening/Closing: Use the control system to operate the pneumatic actuator for opening and closing the valve.

- Flow Control: Ensure the valve is fully open or closed to prevent partial obstruction.

Maintenance

- Regular Inspection: Check for signs of wear or damage. Ensure the actuator and valve components are in good condition.

- Seal Maintenance: Inspect seals periodically and replace if necessary to maintain tight sealing.

- Cleaning: Keep the valve and actuator clean and free from external contaminants.

Safety Precautions

- Always disconnect the air supply before performing maintenance.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Air supply issue or obstruction | Check air supply and clear obstruction |

| Leakage | Worn or damaged seal | Replace the seal |

| Actuator malfunction | Pneumatic fault | Inspect connections and air lines |

Product Show