| Application | General | Place of Origin | ShenZhen, China |

|---|---|---|---|

| Power | Manual,Pneumatic,Electric | Customized support | OEM, ODM |

| Warranty | 2 year | Model Number | Knife Gate Valve |

| Temperature of Media | Medium Temperature, Normal Temperature | Brand Name | JRVAL |

| Media | water,oil,gas,Slurry | Standard or Nonstandard | Standard |

| Product name | knife gate valve stainless steel india | Name | pneumatic knife gate valve dn 800 |

| Type | knife gate valve | Certificate | ISO9001 |

| Working pressure | PN10/PN16 | Working Temperature | 20 -120 |

| MOQ | 1 Piece | Service | Trade Assurance |

| OEM | OEM Service |

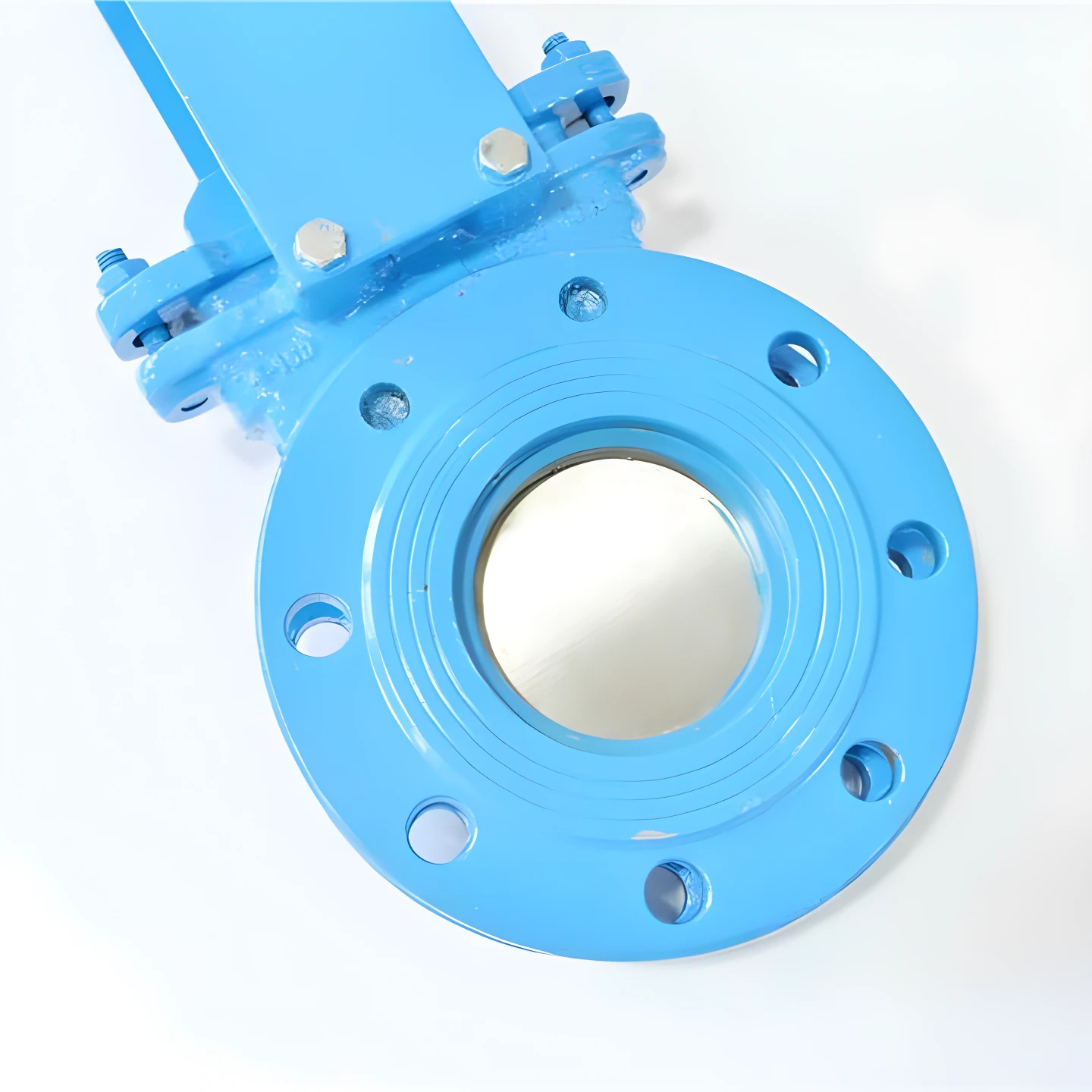

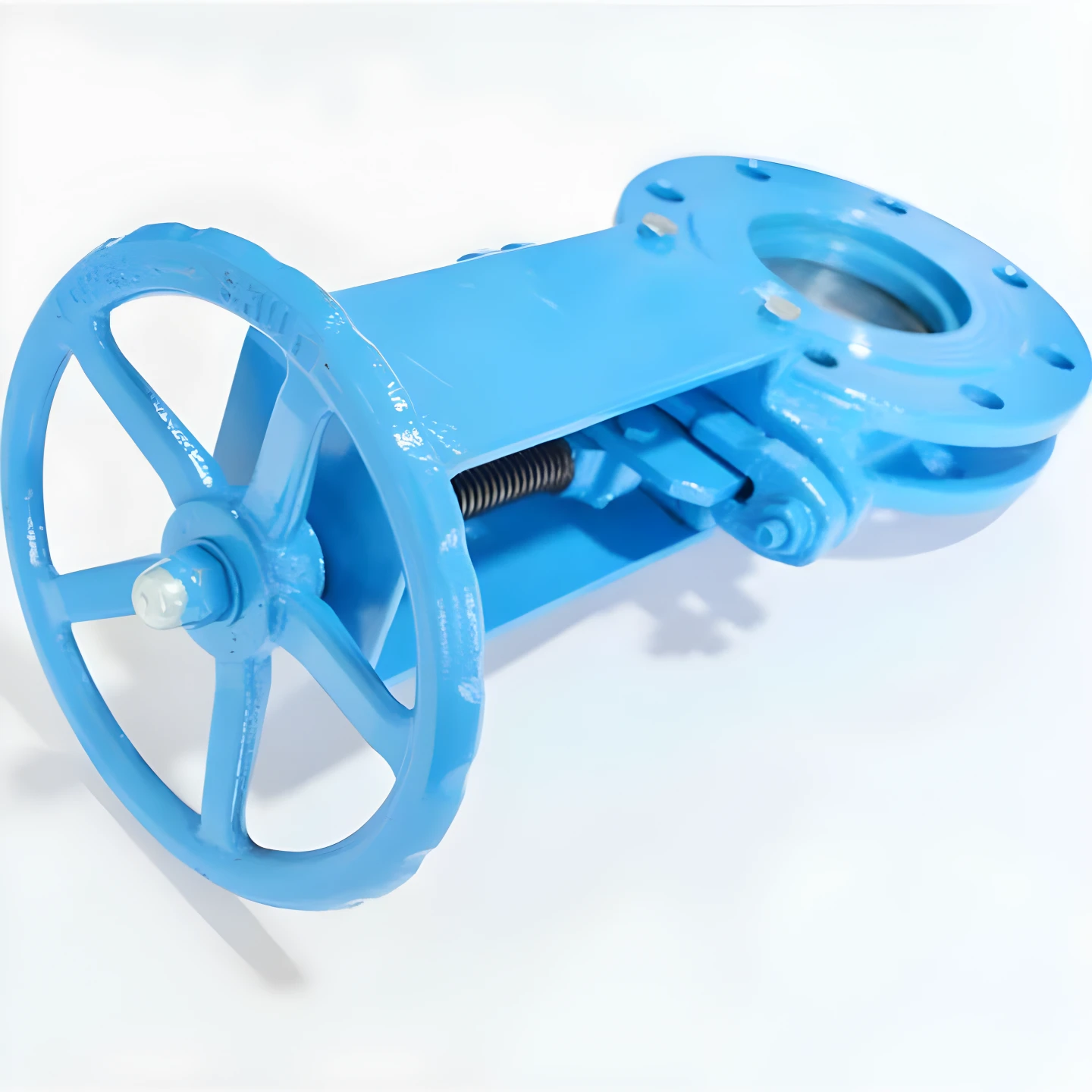

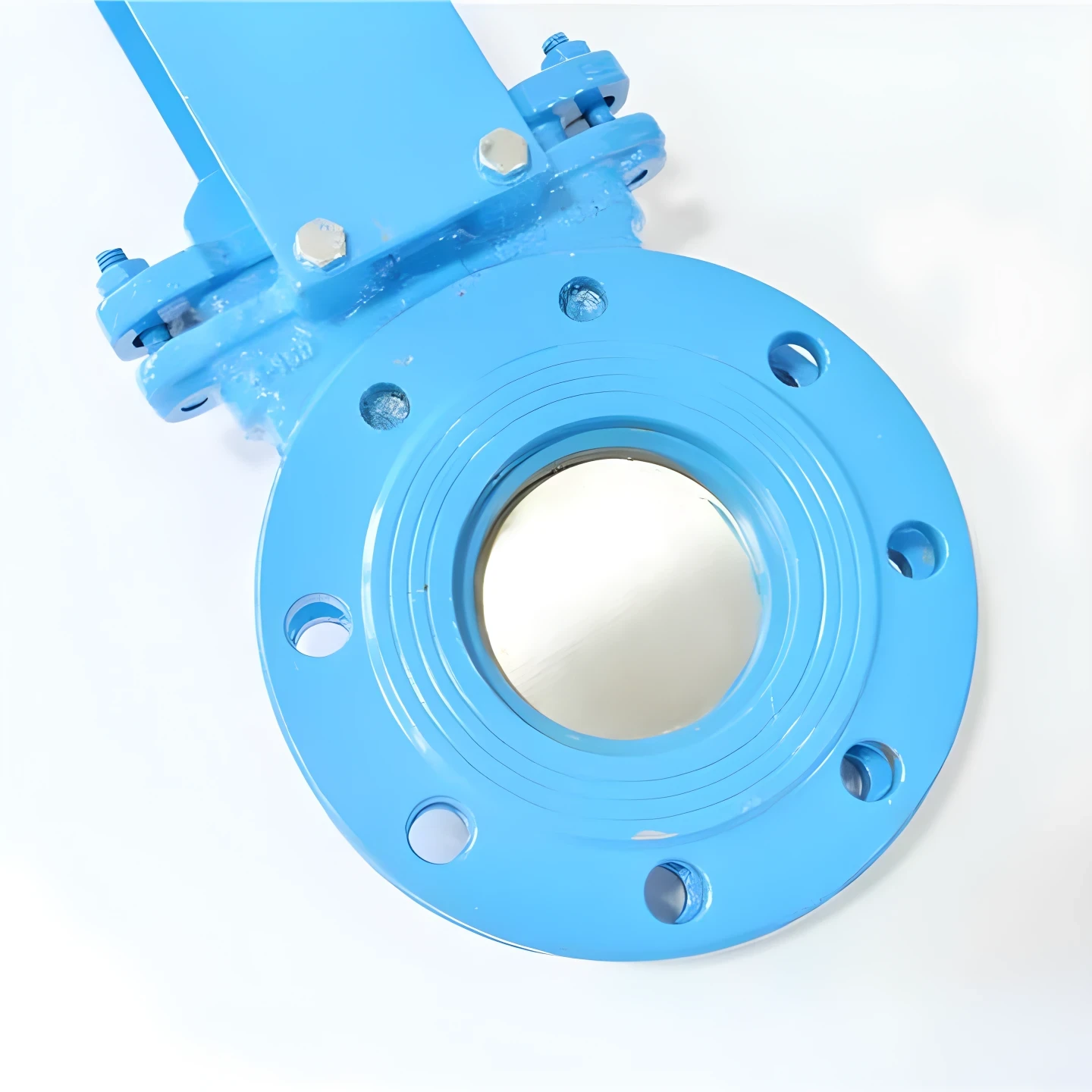

Product Overview

The WCB Flange Manual Knife Gate Valve is designed for reliable flow control in various industrial applications. It is constructed from high-quality carbon steel (WCB) to ensure durability and resistance to wear.

Features

- Robust construction with WCB material

- Manual operation for precise control

- Flange connection for easy installation

- Suitable for a wide range of temperatures and pressures

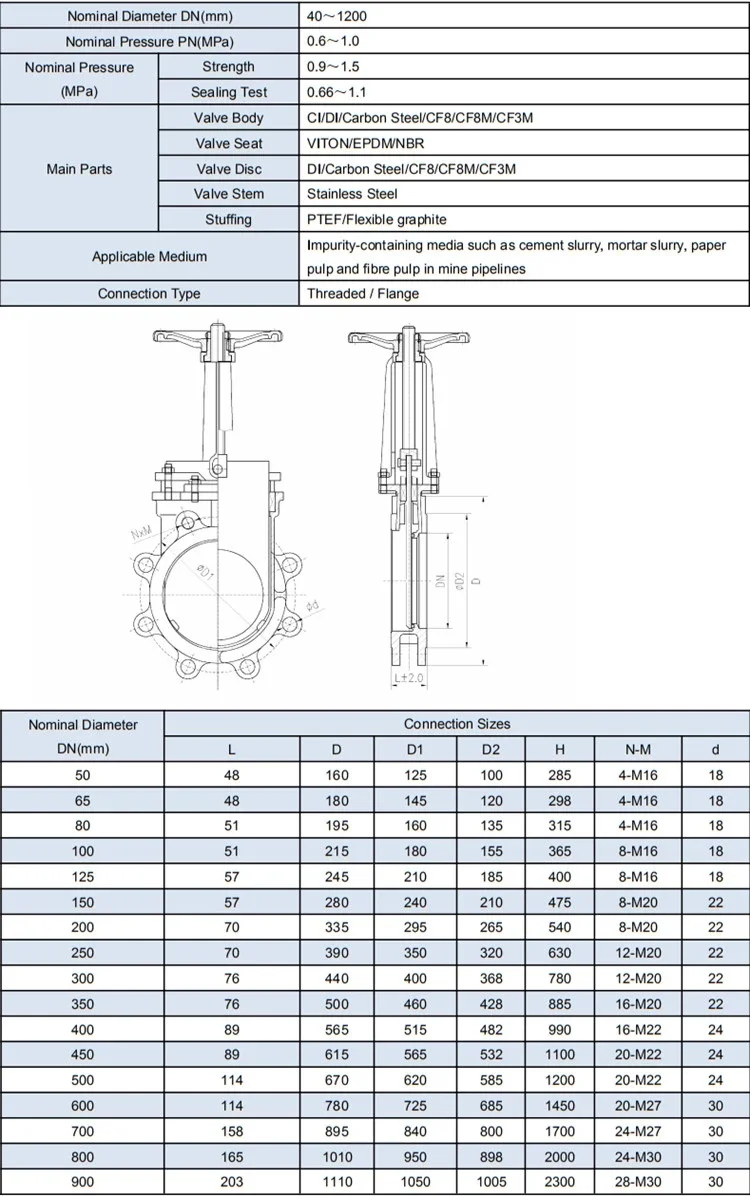

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Knife Gate Valve |

| Material | WCB (Carbon Steel) |

| Operation | Manual |

| Connection Type | Flanged |

| Flange Standard | ANSI B16.5 / DIN / JIS |

| Pressure Rating | PN10 / PN16 / Class 150 |

| Temperature Range | -29°C to 425°C (-20°F to 797°F) |

| Size Range | DN50 to DN600 |

| Seal Material | EPDM / PTFE / Metal |

| Face-to-Face Dimension | As per ANSI B16.10 / DIN EN 558 |

| Leakage Rate | Zero leakage (Metal to Metal) |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Check flange connections for compatibility.

Mounting: Align the valve with the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts in a criss-cross pattern to ensure even pressure.

Inspection: Verify that the valve operates smoothly by manually opening and closing it. Ensure there are no obstructions.

Operation Guidelines

- Opening: Rotate the handwheel counterclockwise to open the valve.

- Closing: Rotate the handwheel clockwise to close the valve.

- Flow Control: Adjust the handwheel to regulate flow as needed.

Maintenance

- Regular Inspection: Check for signs of wear or damage. Ensure the handwheel and stem are lubricated.

- Seal Replacement: Inspect seals periodically and replace if necessary to maintain zero leakage.

- Cleaning: Keep the valve clean and free from external contaminants.

Safety Precautions

- Always depressurize the system before performing maintenance.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the pipeline | Clear the obstruction |

| Leakage | Worn or damaged seal | Replace the seal |

| Difficult operation | Lack of lubrication | Lubricate stem and handwheel |

Product Show