| Application | General | Place of Origin | Zhejiang, China |

|---|---|---|---|

| Power | Manual | Customized support | OEM |

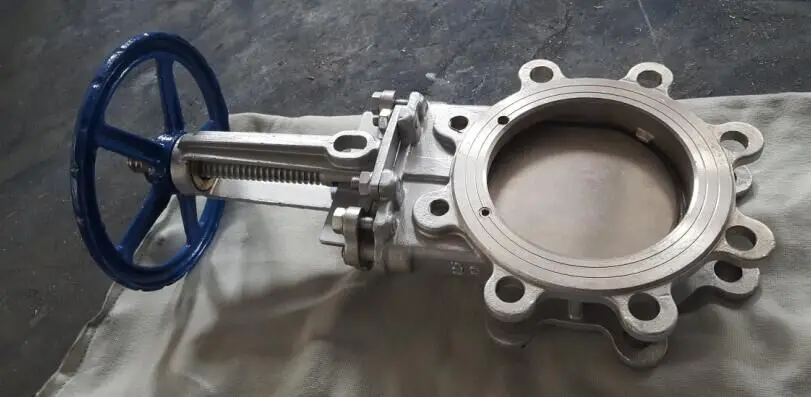

| Model Number | Knife Gate Valve | Temperature of Media | Medium Temperature |

| Brand Name | GZP | Media | Water |

| Standard or Nonstandard | Standard | Port | Full-Port |

| Color | Customer's Request | Valve type | Knife Gate Valve |

| Certificate | ISO9001:2008, CE, TS | Applicable Medium | Water Oil Gas |

| Body Material | Cast Steel, Stainless Steel, Carbon Steel | Size | 2 - 48 Inch |

| Keywords | 2 3 4 5 6 8 10 12 14 16 18 20 24 28 32 36 Inch Knife Gate Valve |

Welcome to High Mpa Valve Factory

>>Standards

Design Standard: MSS SP-81

Inspection & Test: ISO 5208 / MSS SP-81 / API598

Face To Face: MSS SP-81 / DIN3202-K1

End Flange Dimension: ASME B16.5 / JIS B2220

>>Application

Pressure Rating: PN10 / PN16

Size Range: DN50 ~ DN1200 / 2" ~ 48"

Connection: Flange (RF, FF, RTJ) / Butt Welded (BW) / Socket Welded (SW) / Threaded (NPT) / Screwed

Standard: ANSI / JIS / DIN / GB

| Material of Construction | |||

| Cast Iron | IS 210 Gr FG 200 | ||

| Cast Carbon Steel | ASTM A216 Gr WCB / WCC | ||

| Cast Stainless Steel | ASTM A351 Gr CF8 / CF8M | ||

| Forged Carbon Steel | ASTM A105 | ||

| Forged Stainless Steel | ASTM A182 Gr F304 / F316 | ||

| Design & Testing International Standard | |||

| Valve Design | API 594 / API 600 (ISO 10434) / API 6D (ISO 14313) / API 602 / API 603 / API 608 / API 609 / IS 780 / BS 1414 / BS 14846 / BS 1868 / BS 1873 / BS 5351 / ASME B 16.34 (BS 5351) / DIN 3352 / DIN 3356 / DIN 3357 | ||

| Pressure Testing | API 598 / API 600 / API 6D | ||

| Face To Face | ANSI B16.10 | ||

| End Connection | Screwed AS PER BSP/BSPT/NPT, Weld AS PER SW/BW, Flange AS PER RF/RTJ | ||

| Flange Connection | ANSI B16.5 (For NPS≤24) / ANSI B16.47 SERIES B, ANSI 16.47 SERIES A, MSS SP-44 (For NPS >24) | ||

| Butt Weld End | ANSI B16.25 | ||

| Socket Weld End | ANSI B16.11 | ||

| Screwed End | ANSI B1.20.1 (BSP/NPT) | ||

| Wall Thickness | API 600 / BS 1868 | ||

| Pressure Rating | AS PER PN10 PN16 ANSI 125# 150# | ||

| Engineering Option | Gear Operated, Electrical Actuated, Pneumatic Actuate | ||

| Size Range | AS PER NPS 2" - 48" | ||

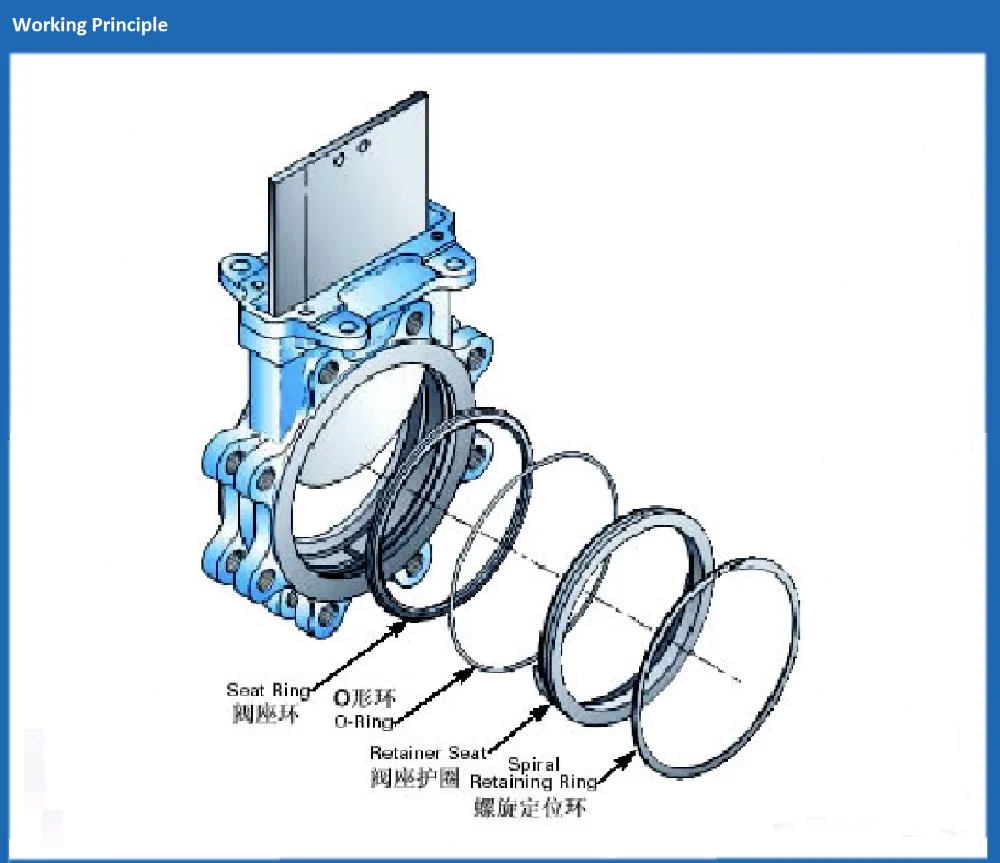

Construction of Gate Valve

Gate valves consists of three main parts: body, bonnet and trim.

The body is generally connected to other equipment by means of flanged, screwed or welded connections.

The bonnet, which containing the moving parts is attached to the body, usually with bolts to permit maintenance.

The valve trim consists of the stem, the gate, the disc or wedge and the seat rings.

Advantages of Gate Valves

>> Good shutoff features

>> Gate valves are bidirectional and therefore they can be used in two directions

>> Pressure loss through the valve is minimal

Introducing the GZP Model Number Knife Gate Valve, expertly designed for a variety of industrial applications. This standard valve is a reliable choice for managing the flow of different media, including water, oil, and gas. The valve's robust construction is made possible with quality materials such as cast steel, stainless steel, and carbon steel, ensuring durability and longevity.

The Knife Gate Valve comes in a comprehensive range of sizes, spanning from 2 to an impressive 48 inches. This versatility allows it to seamlessly integrate into a wide variety of piping systems, catering to diverse industrial applications. Its full-port design is a standout feature, meticulously engineered to minimize pressure loss while facilitating optimal flow characteristics. This means that when fluid moves through the valve, it encounters minimal resistance, which is crucial in maintaining efficiency within the system.

The design significantly enhances operational efficiency, making it particularly advantageous in applications where maximum flow capacity is vital. For instance, in systems handling viscous fluids or large volumes of liquid, the Knife Gate Valve ensures that the flow remains uninterrupted and smooth. Industries such as wastewater treatment, mining, and chemical processing benefit immensely from this valve type as it can handle abrasive materials and rough operating conditions without compromising performance. In settings where rapid opening and closing are necessary, its robust construction allows for reliable operation under varying pressures and temperatures.

Overall, the Knife Gate Valve not only meets but exceeds the demands of modern piping systems, making it an indispensable choice for engineers and operators seeking reliability and efficiency in their fluid control solutions.

Temperature compatibility is crucial in industrial environments; this valve can handle a wide range of temperatures depending on the media type used. For instance, it performs efficiently with medium temperature variations and meets specific operational requirements across various sectors.

Built to meet high-quality standards, the GZP Knife Gate Valve adheres to recognized certifications such as ISO9001:2008, CE, and TS. This commitment to quality ensures that the product not only meets regulatory requirements but also provides peace of mind to clients regarding reliability and safety.

Color customization is available upon request to suit specific project requirements or aesthetic preferences. The valve type - Knife Gate Valve - is notably designed for applications that involve slurries or solids in suspension, making it an ideal choice for water treatment facilities and various chemical processes.

The applicable medium for this valve primarily includes water but also extends to oil and gas functionalities. This versatility makes the GZP Knife Gate Valve an essential component in various infrastructure projects.

In summary, the GZP Knife Gate Valve represents a perfect blend of durability, efficiency, and versatility. It is designed to meet industry standards while providing optimal performance under various conditions. Whether you require control over water flows or need a dependable solution for oil or gas transportation systems, this valve stands poised to meet your needs effectively. Choose GZP for your next project where reliability matters most.