Basic Info.

| Model NO. | DN600-DN2100 | Material | Wcb/Stainless Steel/Ductile Iron |

|---|---|---|---|

| Connection Form | Flange/Wafer | Pressure | Ordinary Pressure |

| Actuator | Handwheel/Pneumatic/Electric | Seal Surface | Wedge Gate Valve |

| Thread Position of Valve Rod | Inside Gate Valve | Usage | Regulation, Emptying, Drain, Flow Control |

| Standard | GB/ANSI/JIS/DIN/API | Application | Industrial Usage, Water Industrial Usage |

| Seat Seal | EPDM/PTFE/Metal | Directioanl Seal | Bi-Directional/Uni-Directional |

| Connectional Type | Flange/Lug | Transport Package | Standard Marine Packing |

| Specification | DN50-DN2600 | Trademark | ZONY/OEM |

| Origin | China | HS Code | 8481804090 |

Product Overview

This valve is designed for applications requiring a hard seal, providing reliable unidirectional flow control.

Features

- Manual operation with handwheel

- Hard seal for enhanced durability

- Cast iron body with robust construction

- Unidirectional flow design

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Unidirectional Knife Gate Valve |

| Model | DZ73H-10 |

| Body Material | Cast Iron |

| Seal Type | Hard Seal |

| Connection Type | Flanged |

| Pressure Rating | PN10 |

| Temperature Range | -10°C to 120°C (14°F to 248°F) |

| Size Range | DN50 to DN600 |

| Leakage Rate | Minimal leakage with hard seal |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Verify flange compatibility.

Mounting: Align the valve with the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts in a criss-cross pattern for even pressure.

Inspection: Verify smooth operation by manually testing the gate. Ensure there are no obstructions.

Operation Guidelines

- Opening/Closing: Operate the valve using the handwheel for opening and closing.

- Flow Control: Ensure the valve is fully open or closed to prevent partial obstruction.

Maintenance

- Regular Inspection: Check for signs of wear or damage. Ensure the gate and seal are in good condition.

- Seal Maintenance: Inspect the hard seal periodically and replace if necessary to maintain minimal leakage.

- Cleaning: Keep the valve clean and free from external contaminants.

Safety Precautions

- Always depressurize the system before performing maintenance.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction or mechanical issue | Clear obstruction and inspect mechanism |

| Leakage | Worn or damaged seal | Replace the seal |

| Difficult operation | Mechanical wear | Lubricate and inspect for wear |

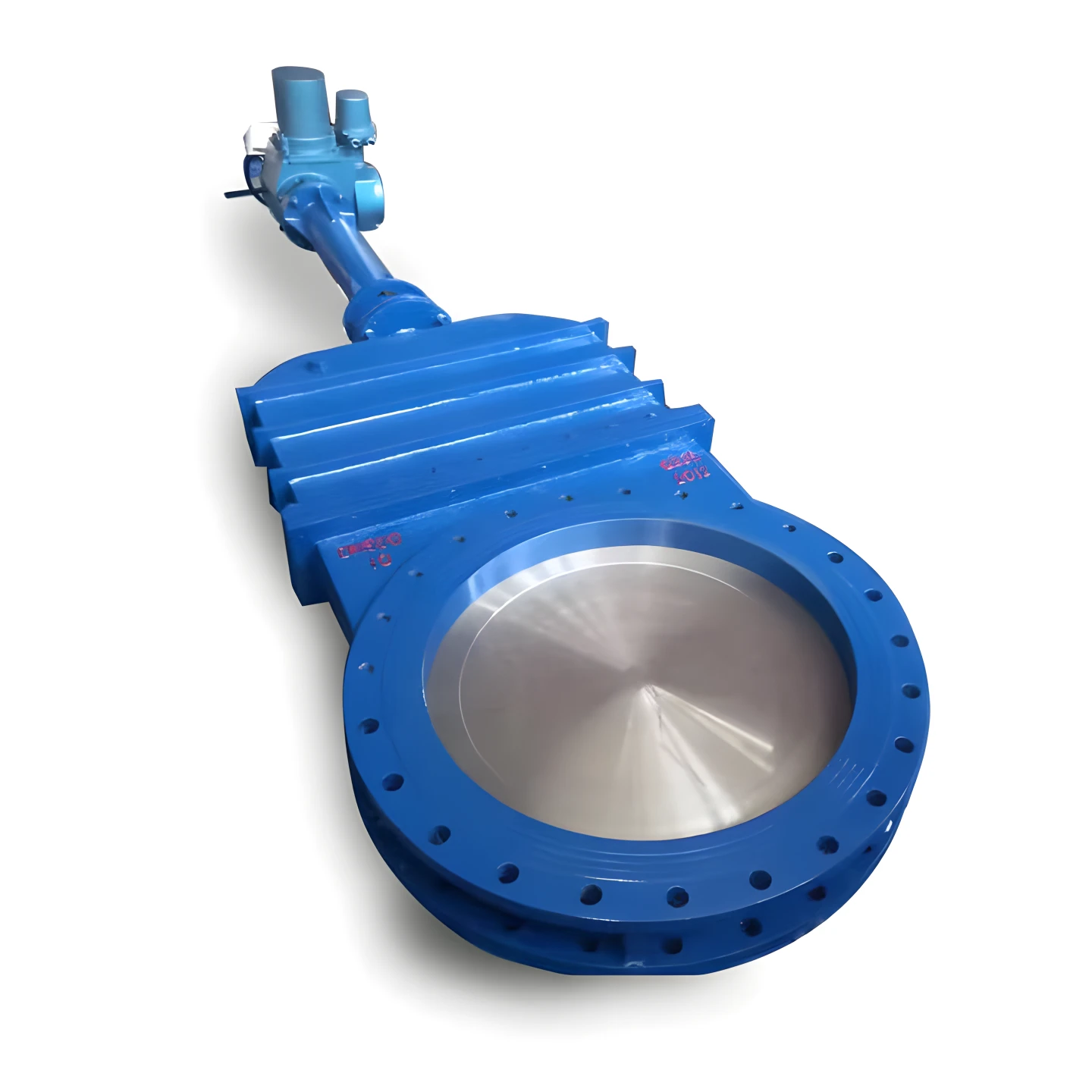

Product Show