| Application | General | Place of Origin | ShenZhen, China |

|---|---|---|---|

| Power | DN40-1200 | Customized support | OEM, ODM |

| Warranty | 3 years | Temperature of Media | Medium Temperature |

| Media | Water | Product name | Knife Gate Valve |

| Size | DN40-1200 | Color | Customized Color |

Product Overview

This electric knife gate valve is designed for a wide range of applications, offering precise control and reliable performance in handling various fluids and slurries. It features an electric actuator for automated operation and is suitable for pipe sizes ranging from DN40 to DN1200.

Features

- Electric actuator for automated operation

- Suitable for DN40 to DN1200 pipe sizes

- Robust construction for durability

- Uni-directional flow design

- Ideal for handling fluids and slurries

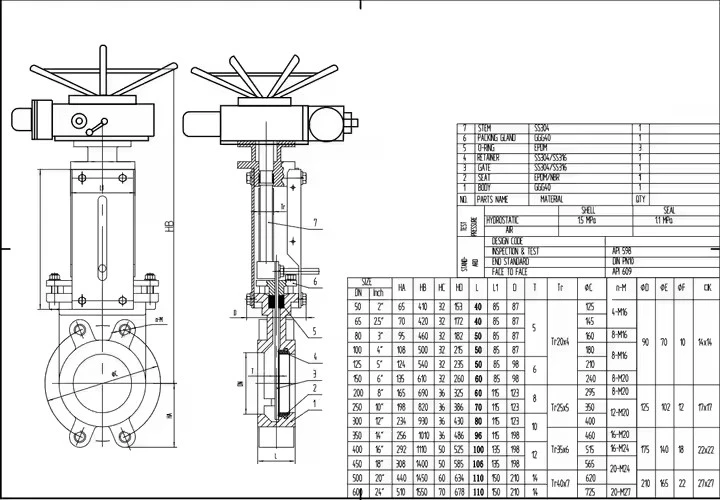

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | Knife Gate Valve |

| Body Material | Ductile Iron or Stainless Steel |

| Operation | Electric Actuator |

| Connection Type | Flanged |

| Pressure Rating | PN10/16 |

| Temperature Range | -20°C to 120°C (-4°F to 248°F) |

| Size Range | DN40 to DN1200 |

| Seal Material | Reinforced Rubber or Metal |

| Leakage Rate | Minimal leakage |

| Power Supply | As specified (e.g., 220V AC, 380V AC) |

Installation Instructions

Preparation: Ensure the pipeline is clean and free from debris. Verify flange compatibility and check that the electric actuator is properly configured.

Mounting: Align the valve with the pipeline flanges. Use appropriate gaskets and bolts to secure the valve. Tighten bolts in a criss-cross pattern for even pressure distribution.

Electrical Connection: Connect the electric actuator to the power supply according to the manufacturer's specifications. Ensure all electrical connections are secure and compliant with local regulations.

Inspection: Test the actuator to ensure smooth operation and check for any obstructions in the valve.

Operation Guidelines

- Opening/Closing: Use the control system to operate the electric actuator for opening and closing the valve.

- Flow Control: Ensure the valve is fully open or closed to prevent partial obstruction and ensure optimal flow control.

- Manual Override: In case of power failure, use the manual override mechanism (if available) to operate the valve.

Maintenance

- Regular Inspection: Perform regular inspections for signs of wear or damage. Ensure the actuator and valve components are in good condition.

- Seal Maintenance: Inspect seals periodically and replace if necessary to maintain tight sealing and prevent leakage.

- Cleaning: Keep the valve and actuator clean and free from external contaminants to ensure smooth operation.

Safety Precautions

- Always disconnect the power supply before performing any maintenance or inspection.

- Use appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure all personnel are trained in valve operation and safety protocols.

Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Electrical issue or obstruction | Check power supply and clear obstruction |

| Leakage | Worn or damaged seal | Replace the seal |

| Actuator malfunction | Electrical fault | Inspect connections and power supply |

Product Show