| Application | General | Place of Origin | China |

|---|---|---|---|

| Power | Manual | Customized support | OEM, ODM |

| Warranty | 1 year | Model Number | PZ73W |

| Temperature of Media | Medium Temperature, Normal Temperature | Brand Name | DKV |

| Media | Water | Connection | flange |

| Medium | Water Oil Gas | Body material | SS304/WCB |

| Pressure | 1.0~1.6MPa | Working Temperature | 0°C to 80°C NBR, 150°C Metal |

| Seal Material | Stainless Steel+STL;EPDM (120°C) /Viton(200°C)/PTFE(200°C) /NBR(90°C) |

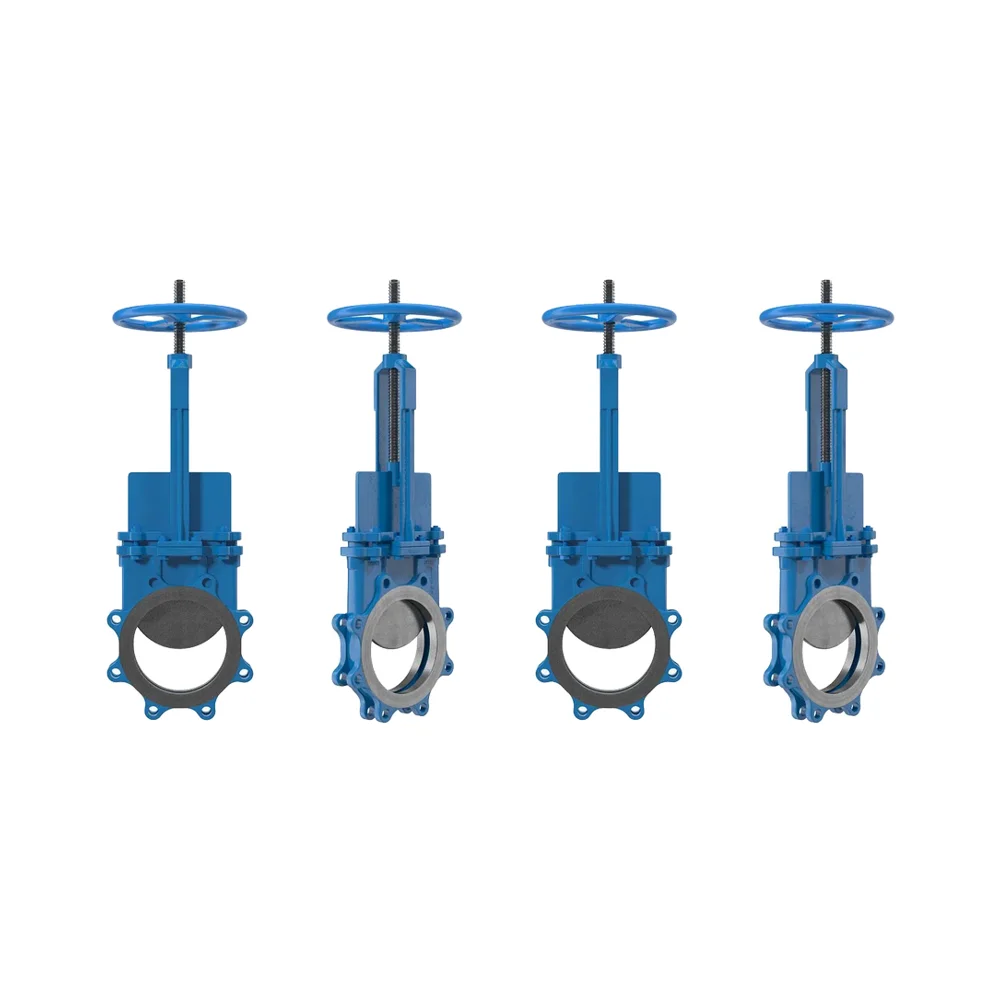

1. Introduction

The Stainless Steel Manual Handle Wheel Knife Gate Valve is designed for durability and efficient performance in handling various media, especially in challenging environments. This valve features a manual handle wheel for easy operation, a PN10 flanged connection for secure installation, and is constructed from high-quality stainless steel, cast iron, or cast steel (WCB) to meet diverse application needs.

2. Features

- Material Options:

- Stainless Steel (SS304/SS316)

- Cast Iron

- Cast Steel (WCB)

- Design: Knife gate design to cut through thick and abrasive media, ensuring smooth flow and minimal clogging.

- Seal: Resilient seal providing tight closure and preventing leakage.

- Actuation: Manual operation with a handle wheel.

- Connection: PN10 flanged ends for easy installation and secure connection.

- Pressure Rating: Suitable for medium pressure applications (PN10).

3. Applications

- Mining industry.

- Wastewater treatment plants.

- Pulp and paper industry.

- Chemical processing.

- Power generation.

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | Various sizes available |

| Body Material | Stainless Steel, Cast Iron, Cast Steel (WCB) |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) |

| Pressure Rating | PN10 |

| Temperature Range | -10°C to 200°C (14°F to 392°F) |

| Connection Type | Flanged (PN10) |

| Face-to-Face Dimension | According to ISO 5752 |

| Media | Slurry, abrasive and viscous fluids |

| Operating Pressure | 1.0 MPa (PN10) |

| Actuation | Manual (Handle Wheel) |

| Leakage Rate | Zero leakage (resilient seal) |

| Testing Standard | API 598 |

5. Installation Instructions

- Preparation: Ensure the pipeline is clean and free of debris.

- Alignment: Align the valve with the pipeline flanges.

- Bolting: Secure the valve using appropriate bolts and nuts, ensuring even tightening.

- Handle Wheel Operation: Ensure the handle wheel is properly attached and operates smoothly.

- Testing: Test the valve for proper operation and check for leaks.

6. Maintenance

- Regular Inspection: Periodically inspect the valve for signs of wear or damage.

- Seal Replacement: Replace the seals if leakage is detected.

- Stem Maintenance: Ensure the stem operates smoothly and is free from debris.

- Gate Inspection: Inspect the gate for wear and replace if necessary.

7. Safety Precautions

- Ensure the pipeline is depressurized before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Difficulty in manual operation | Debris or damage in the stem or gate | Clean and inspect the stem and gate |

Product Show