| Application | General | Place of Origin | Shenzhen, China |

|---|---|---|---|

| Power | Pneumatic | Customized support | OEM |

| Warranty | 1 year | Model Number | Flanged Pneumatic Knife Gate Valve |

| Temperature of Media | Medium Temperature | Brand Name | COVNA |

| Media | Water | Type | Pneumatic Knife Gate Valve |

| Acting Mode | Double Acting/Single Acting Pneumatic Actuator | Air Supply Pressure | 0.4MPa~0.6MPa |

| Media | Air, Gas, Oil, Liquid | Temperature of Media | t<180°C |

| Pressure | 0.6MPa~2.5MPa | Sealing Material | PTFE, Metal Seated |

| End Connection | Flange | Certificate | CE, RoHS, ISO9001, TUV |

| Certification | ROHS,CE,ISO9001 |

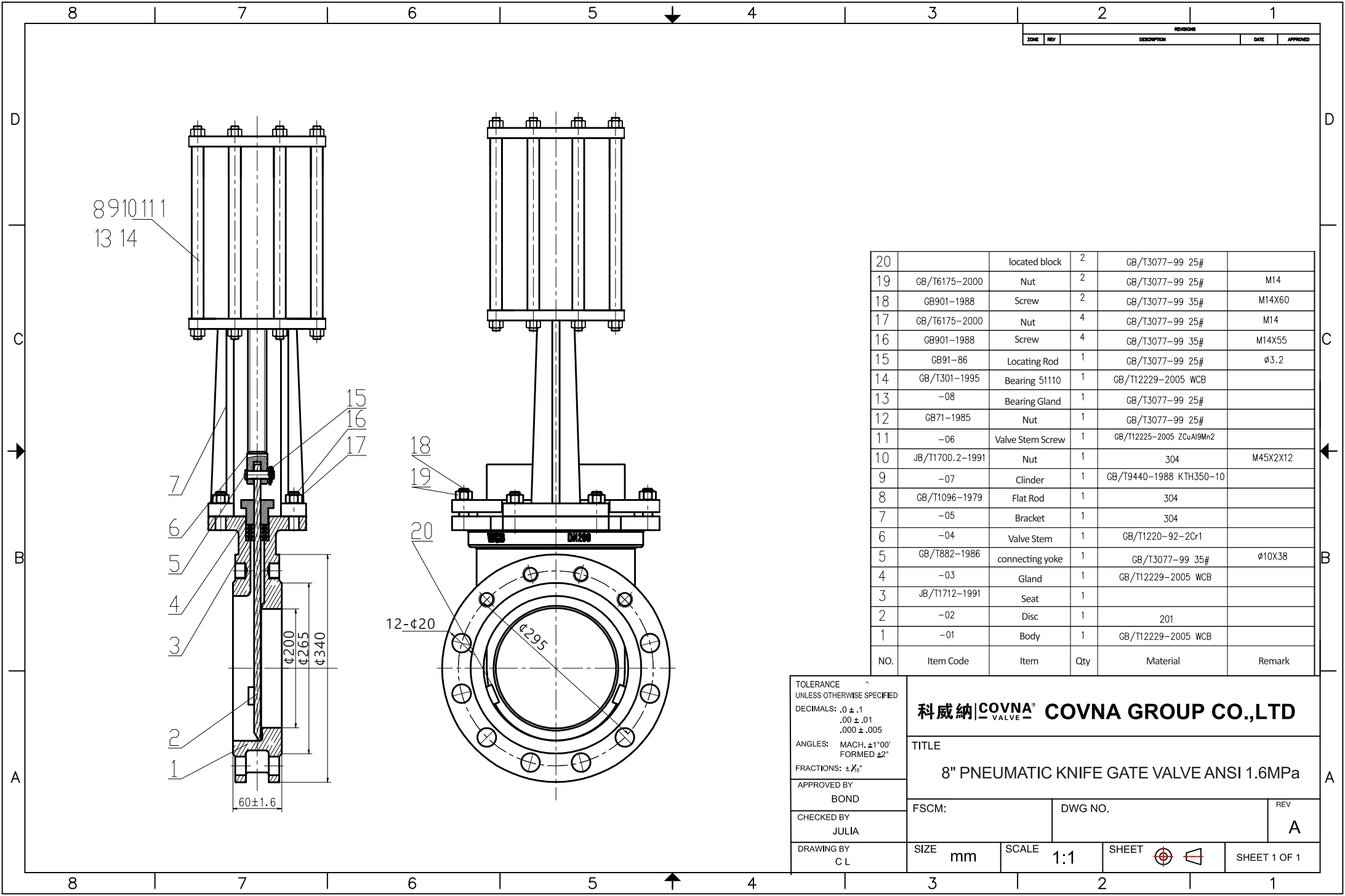

1. Introduction

The 4-inch Stainless Steel Pneumatic Flange Type Slurry Knife Gate Valve is engineered for the efficient control of slurry and other abrasive or viscous media in industrial applications. The valve's robust construction and pneumatic actuation make it ideal for heavy-duty use in mining, wastewater treatment, and other industries handling slurries.

2. Features

- Material: High-grade stainless steel body for excellent corrosion and abrasion resistance.

- Design: Knife gate design to cut through thick and abrasive media, ensuring smooth flow and minimal clogging.

- Seal: Resilient seal providing tight closure and preventing leakage.

- Actuation: Pneumatic actuator for automated and efficient operation.

- Connection: Flanged ends for easy installation and secure connection.

- Size: 4 inches (DN100).

- Pressure Rating: Suitable for medium-pressure applications.

3. Applications

- Mining industry.

- Wastewater treatment plants.

- Pulp and paper industry.

- Chemical processing.

- Power plants.

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | 4 inches (DN100) |

| Body Material | Stainless Steel (SS304/SS316) |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) |

| Pressure Rating | PN10 |

| Temperature Range | -10°C to 120°C (14°F to 248°F) |

| Connection Type | Flanged |

| Face-to-Face Dimension | According to ISO 5752 |

| Media | Slurry, abrasive and viscous fluids |

| Operating Pressure | 1.0 MPa |

| Actuation | Pneumatic |

| Air Supply Pressure | 0.4 - 0.7 MPa |

| Leakage Rate | Zero leakage (resilient seal) |

| Testing Standard | API 598 |

5. Installation Instructions

- Preparation: Ensure the pipeline is clean and free of debris.

- Alignment: Align the valve with the pipeline flanges.

- Bolting: Secure the valve using appropriate bolts and nuts, ensuring even tightening.

- Pneumatic Connection: Connect the pneumatic actuator to the air supply according to the manufacturer’s instructions.

- Testing: Test the valve for proper operation and check for leaks.

6. Maintenance

- Regular Inspection: Periodically inspect the valve and actuator for signs of wear or damage.

- Seal Replacement: Replace the seals if leakage is detected.

- Stem Maintenance: Ensure the stem operates smoothly and is free from debris.

- Actuator Maintenance: Follow the actuator manufacturer’s maintenance guidelines.

7. Safety Precautions

- Ensure the air supply is disconnected before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Actuator malfunction | Air supply issue or actuator failure | Check air supply and inspect the actuator |

Feature of COVNA Pneumatic Knite Gate Valve:

● Integral structure, ultra-thin design, full-diameter flow, not easy to leak, easy to disassemble● Movable sealing structure, good sealing performance, strong wear resistance, automatic compensation, long life

● Fixed guide claw design, replacing the groove structure, not easy to accumulate, and prevent blocking

● Double bearing design, small torque, frequent opening and closing, no vibration, no noise

● Knife-shaped cutting edge, strong cutting force, self-cleaning function, suitable for fiber particle fluid

| Nominal Pressure | 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa, 150Lb | Nominal Diameter | DN50~DN1000 |

| Operating Temperature | -30℃ ~300℃(Range of temperature subject to the material of sealing and property of medium) | Flange Drilling | ANSI B16.5, GB/T9113, JB/T79, HG, SH, JIS, DIN, NF, BS |

| Main Materials | C.I, WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8, CF8M, CF3,CF3M. 2Cr25Ni20 | Seal Type | Stainless steel hard seal, Teflon soft seal |

| Applicable Medium | Mud, material, viscous, granular fluid | Connection Type | Flanged Type, Lug type, Wafer type |

| Leakage | Stainless steel hard seal: Grade D (Liquid0.1XDN mm3/s) | Teflon Soft Seal | Grade A (Zero Leakage) |

| Accessories | 1.Flange 2.Solenoid valve 3.Air filter 4.Limit switch | Air-supply pressure | 0.4~0.6MPa |

| Solenoid valve voltage | DC24V AC220V | Optional Accessories | Namur Solenoid Valve, Limit Switch, F.R.L, Position Indicator, Manual Device |