| Application | General | Place of Origin | Shenzhen, China |

|---|---|---|---|

| Power | Manual | Customized support | OEM, ODM |

| Warranty | 2 years | Model Number | PZ73H |

| Temperature of Media | High Temperature, Low Temperature, Medium Temperature, Normal Temperature | Brand Name | SHANGCHENG |

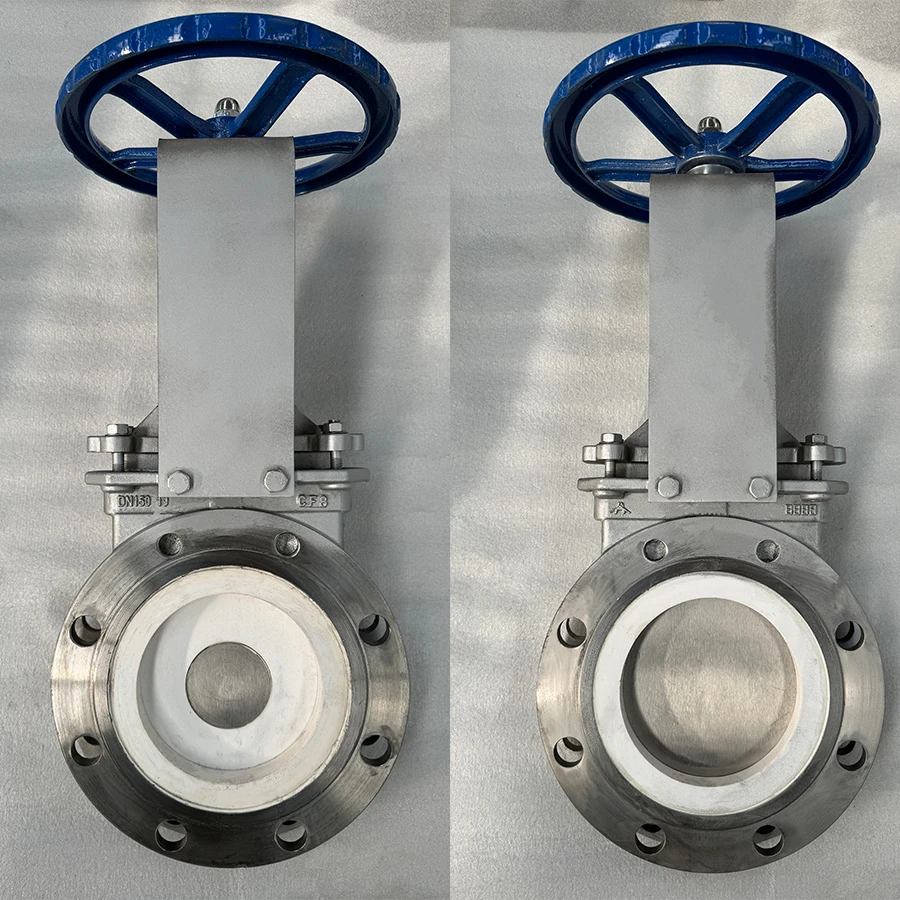

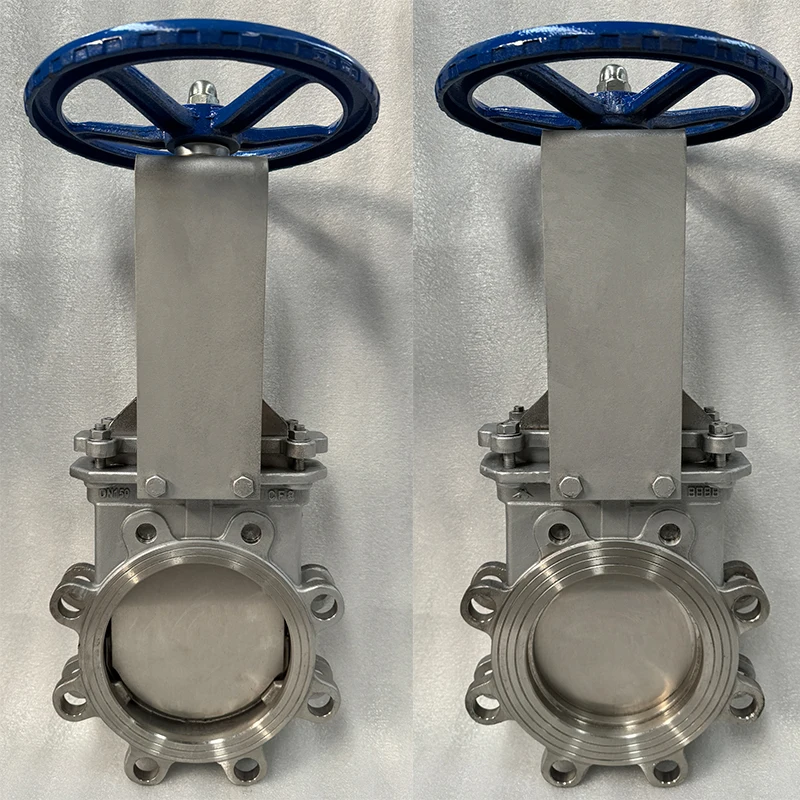

| Media | pulp | product name | Cast steel knife gate valve |

| Working pressure | 1.0-1.6Mpa (10-25bar) | Stem | Stainless iron |

| Body material | Cast steel (WCB) | Valve plate material | SS201/SS304/SS316/SS316L |

| sealing material | SS304/fluororubber/silicone rubber | temperature | -29℃-427℃ |

| Working medium | Sewage, pulp, etc | Connection type | Clamp valves/Flange link |

| operation | Hand wheel, pneumatic, electric |

1. Introduction

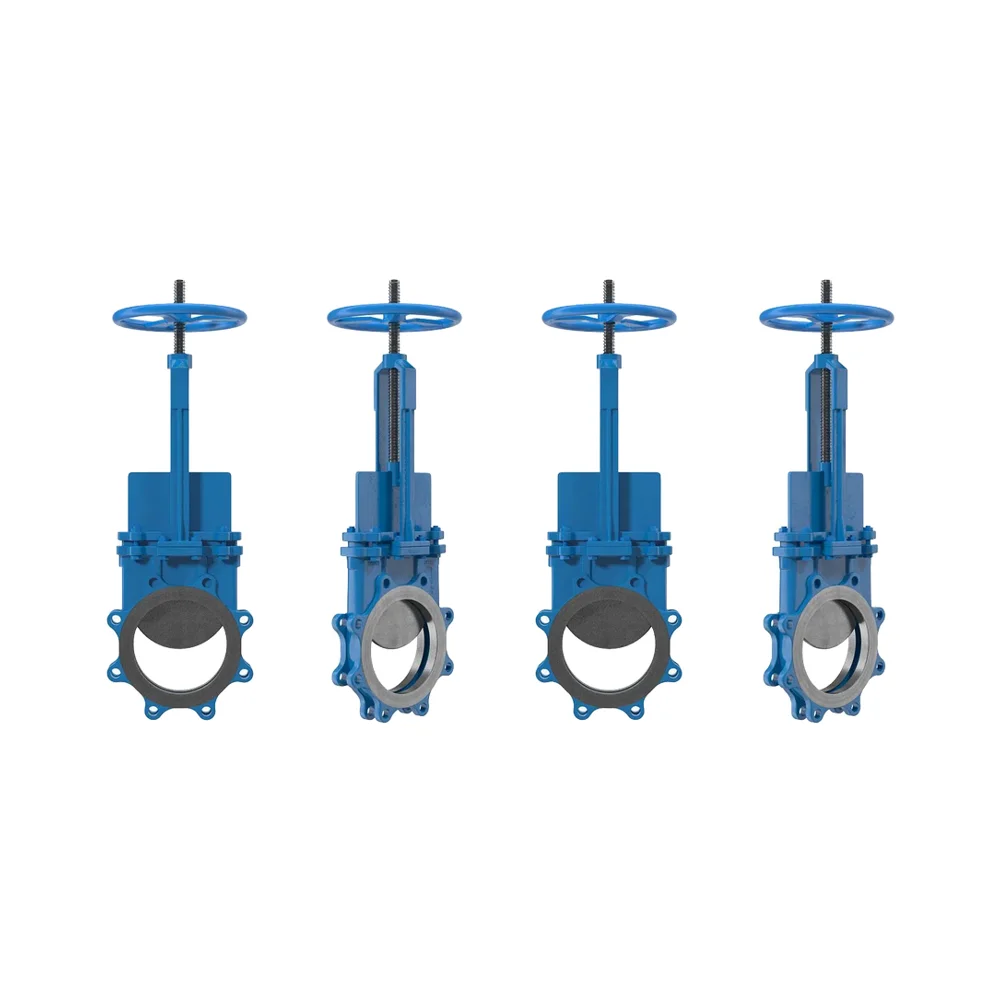

The Cast Steel Lug Type Knife Gate Valve with a One-Way Seal is designed for handling abrasive and corrosive applications where unidirectional sealing is required. This valve is ideal for industries such as mining, wastewater treatment, and pulp & paper, where reliable performance and durability are essential.

2. Features

- Material: Cast steel body for enhanced strength and corrosion resistance.

- Design: Lug type knife gate design for easy installation and maintenance.

- Seal: One-way resilient seal ensuring tight closure in one direction.

- Actuation: Available in manual, pneumatic, and hydraulic operation.

- Connection: Lugged ends for secure and versatile installation.

3. Applications

- Mining industry.

- Wastewater treatment plants.

- Pulp and paper industry.

- Chemical processing industry.

- Power plants.

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | Various sizes available |

| Body Material | Cast Steel |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) |

| Pressure Rating | PN16 |

| Temperature Range | -10°C to 120°C (14°F to 248°F) |

| Connection Type | Lugged |

| Face-to-Face Dimension | According to ISO 5752 |

| Media | Slurry, abrasive fluids, corrosive substances |

| Operating Pressure | 1.6 MPa |

| Actuation Options | Manual, Pneumatic, Hydraulic |

| Leakage Rate | Zero leakage (one-way seal) |

| Testing Standard | API 598 |

5. Installation Instructions

- Preparation: Ensure the pipeline is clean and free of debris.

- Alignment: Align the valve with the pipeline lugs.

- Bolting: Secure the valve using appropriate bolts and nuts, ensuring even tightening.

- Actuator Connection: If using a pneumatic or hydraulic actuator, connect it according to the manufacturer's instructions.

- Testing: Test the valve for proper operation and check for leaks.

6. Maintenance

- Regular Inspection: Periodically inspect the valve for signs of wear or damage.

- Seal Replacement: Replace the seals if leakage is detected.

- Stem Maintenance: Ensure the stem operates smoothly and is free from debris.

- Actuator Maintenance: Follow the actuator manufacturer's maintenance guidelines if applicable.

7. Safety Precautions

- Ensure the pneumatic or power supply is disconnected before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Actuator malfunction (if applicable) | Actuator failure | Inspect and repair/replace actuator |