| Place of Origin | Shandong, China | Power | Manual |

|---|---|---|---|

| Customized support | OEM | Warranty | 1 year |

| Model Number | DN50 | Temperature of Media | Normal Temperature |

| Brand Name | GYUANYU | Media | Media: powder |

| Standard or Nonstandard | Standard | knife gate valves | gate valve |

| Seal Material | PTFE | Color | Blue |

| Body material | CF8 | Packing | Carton |

| Main Materials | Stainess Steel |

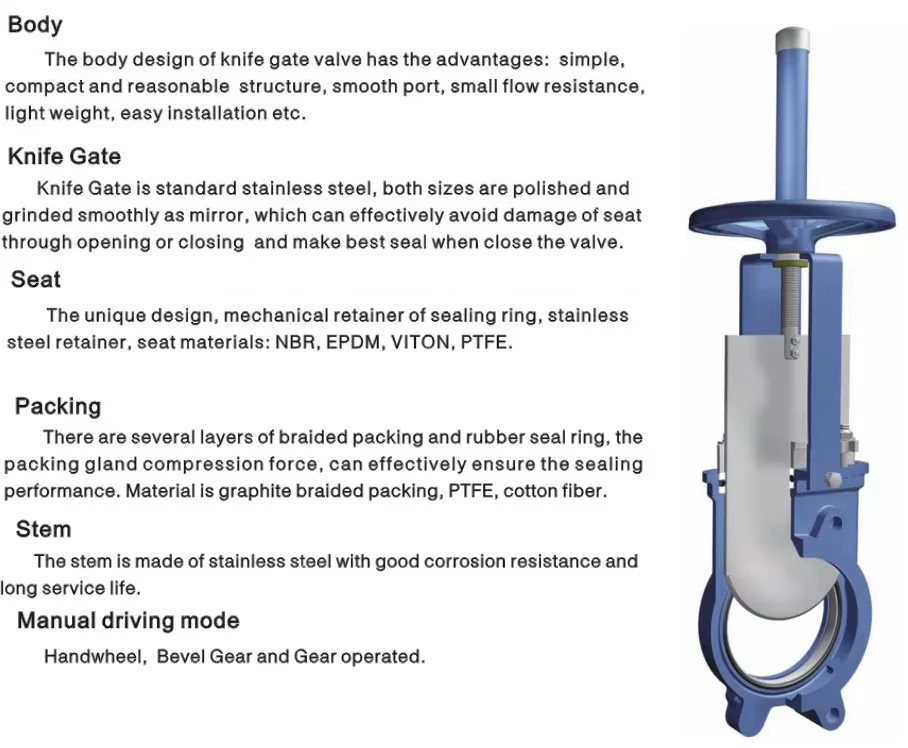

1. Introduction

The Cast Iron Slurry Knife Gate Valve is specifically designed for handling abrasive and corrosive slurry applications. Its robust construction ensures durability and reliable performance in demanding environments such as mining, wastewater treatment, and the pulp & paper industry.

2. Features

- Material: Cast iron body for strength and durability.

- Design: Knife gate design to cut through thick media, ensuring smooth flow and minimal clogging.

- Seal: Resilient seal providing tight closure and preventing leakage.

- Actuation: Available in manual, pneumatic, and hydraulic operation.

- Connection: Flanged ends for easy installation and secure connection.

3. Applications

- Mining industry.

- Wastewater treatment plants.

- Pulp and paper industry.

- Chemical processing industry.

- Power plants.

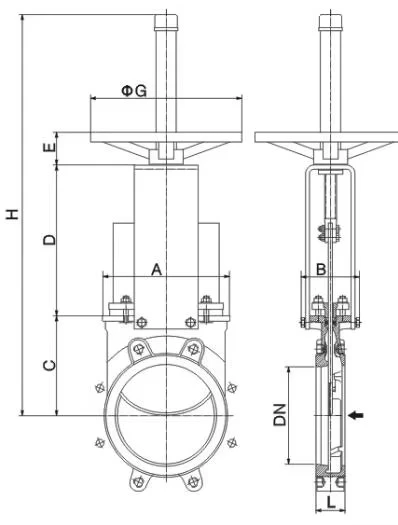

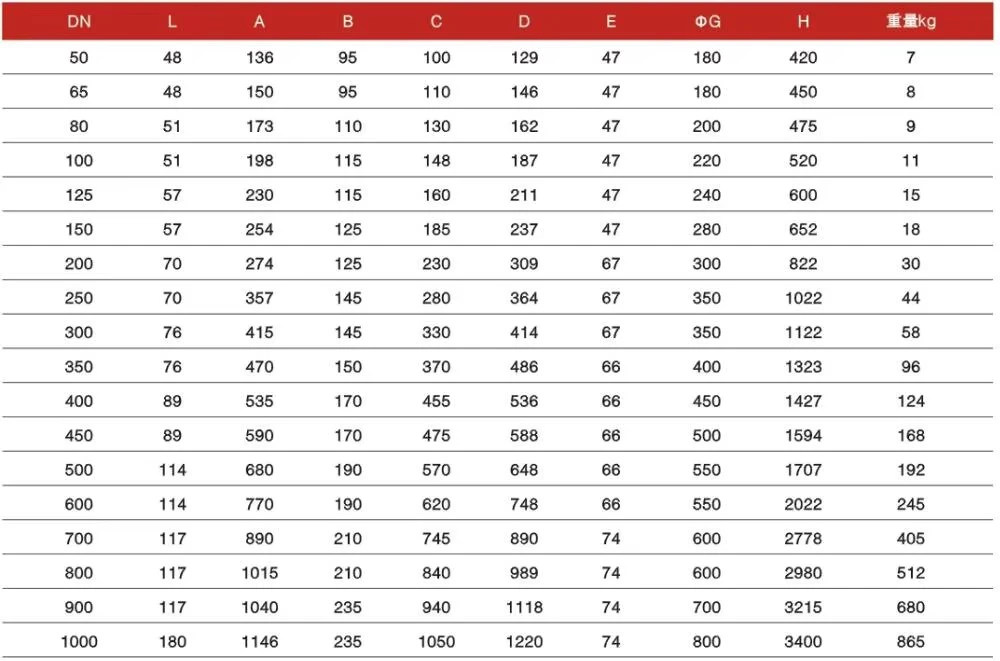

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Size | 8 inches (DN200) and other sizes available |

| Body Material | Cast Iron |

| Gate Material | Stainless Steel (SS304/SS316) |

| Seal Material | Resilient (EPDM, NBR, etc.) |

| Pressure Rating | PN16 |

| Temperature Range | -10°C to 120°C (14°F to 248°F) |

| Connection Type | Flanged |

| Face-to-Face Dimension | According to ISO 5752 |

| Media | Slurry, abrasive fluids, corrosive substances |

| Operating Pressure | 1.6 MPa |

| Actuation Options | Manual, Pneumatic, Hydraulic |

| Leakage Rate | Zero leakage (resilient seal) |

| Testing Standard | API 598 |

5. Installation Instructions

- Preparation: Ensure the pipeline is clean and free of debris.

- Alignment: Align the valve with the pipeline flanges.

- Bolting: Secure the valve using appropriate bolts and nuts, ensuring even tightening.

- Actuator Connection: If using a pneumatic or hydraulic actuator, connect it according to the manufacturer's instructions.

- Testing: Test the valve for proper operation and check for leaks.

6. Maintenance

- Regular Inspection: Periodically inspect the valve for signs of wear or damage.

- Seal Replacement: Replace the seals if leakage is detected.

- Stem Maintenance: Ensure the stem operates smoothly and is free from debris.

- Actuator Maintenance: Follow the actuator manufacturer's maintenance guidelines if applicable.

7. Safety Precautions

- Ensure the pneumatic or power supply is disconnected before performing any maintenance.

- Use appropriate personal protective equipment (PPE) when handling the valve.

- Follow all relevant safety standards and guidelines.

8. Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve does not open/close | Obstruction in the gate area | Inspect and clean the gate area |

| Leakage through the seal | Worn or damaged seal | Replace the seal |

| Actuator malfunction (if applicable) | Actuator failure | Inspect and repair/replace actuator |

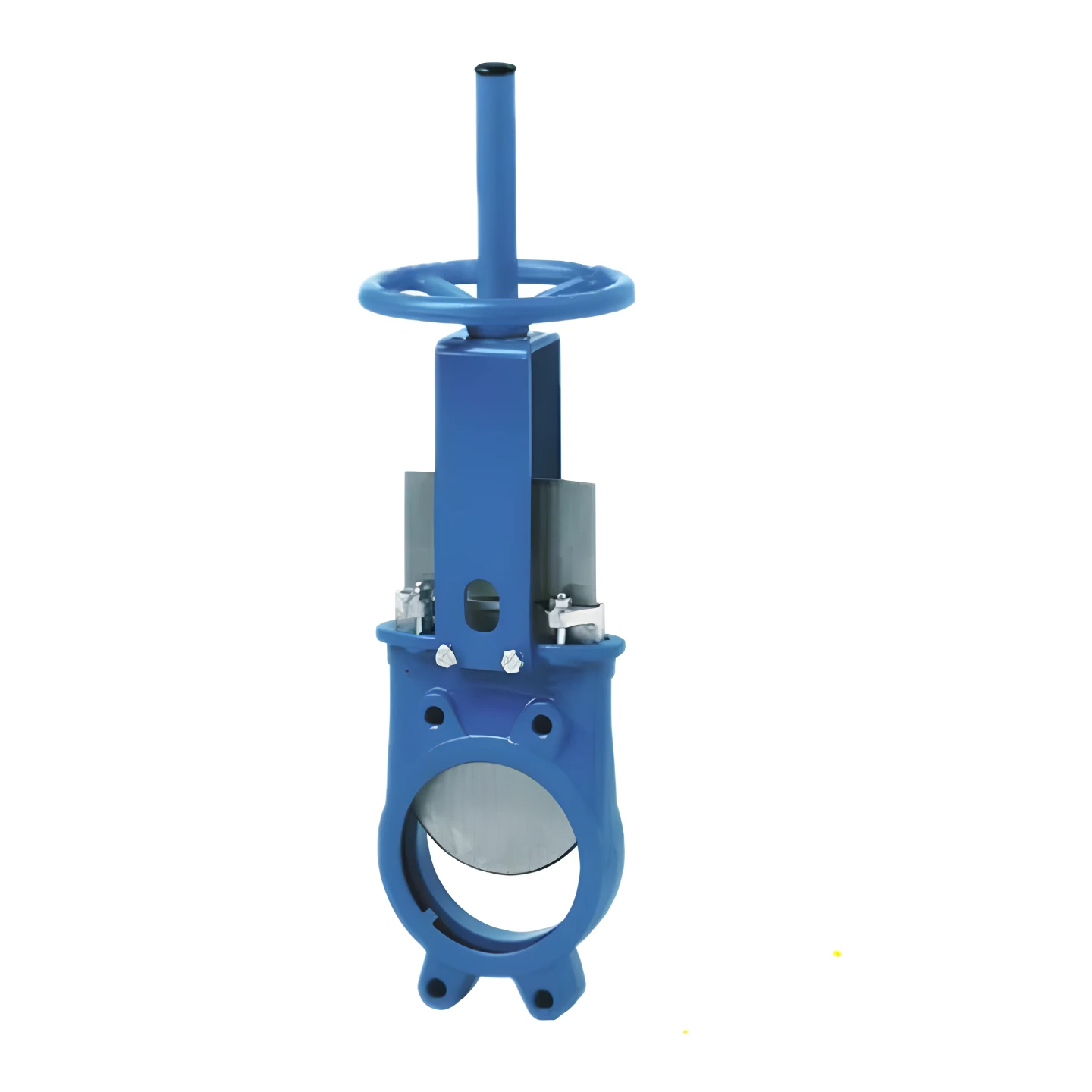

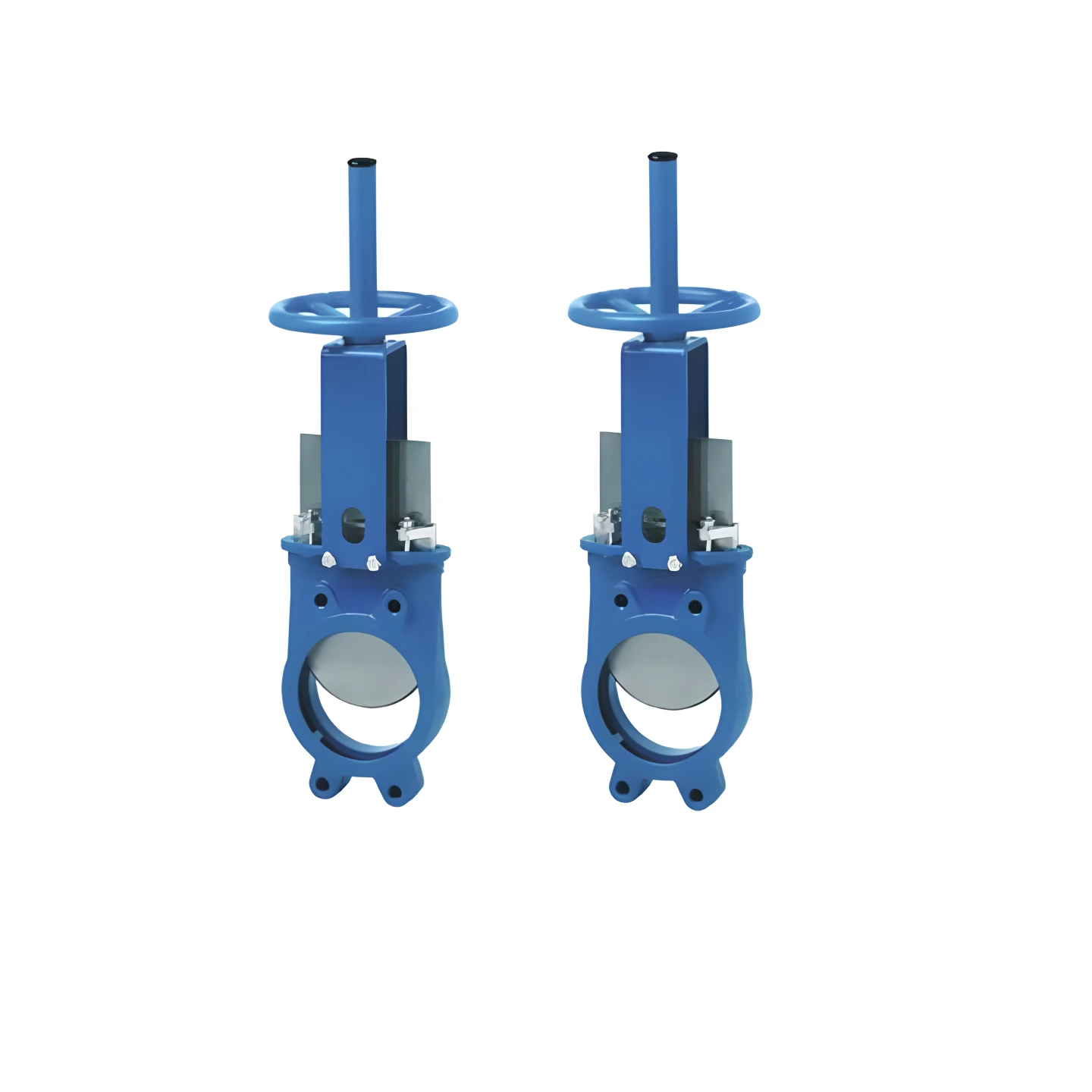

Product Show