Key Takeaways

Pneumatic knife gate valves offer an efficient solution for controlling fluid flow in various industrial applications. The pneumatic actuator knife gate valve configuration is designed to provide reliable and precise operation under demanding conditions. Key features include robust construction, which ensures durability, and the ability to handle both slurries and liquids with high solid content. The ease of operation provided by pneumatic actuation enhances overall efficiency, reducing downtime associated with manual systems.

In Sharjah, several pneumatic knife gate valve manufacturers are available, each offering their own unique set of advantages. Selecting the right manufacturer involves evaluating not only product specifications but also service reliability and support capabilities. Understanding the differences between pneumatic knife edge gate valves and other types can guide decision-making in applications where precise flow control is paramount. These valves are ideal for sectors such as wastewater treatment, mining, and power generation.

When it comes to maintenance, pneumatic knife gate valves are generally easier to service than mechanical alternatives due to their simpler design. This simplicity translates into longer operational life and lower overall maintenance costs, making them a favored choice among engineers seeking dependable performance in challenging environments.

Pneumatic Actuator Knife Gate Valves: Features and Advantages

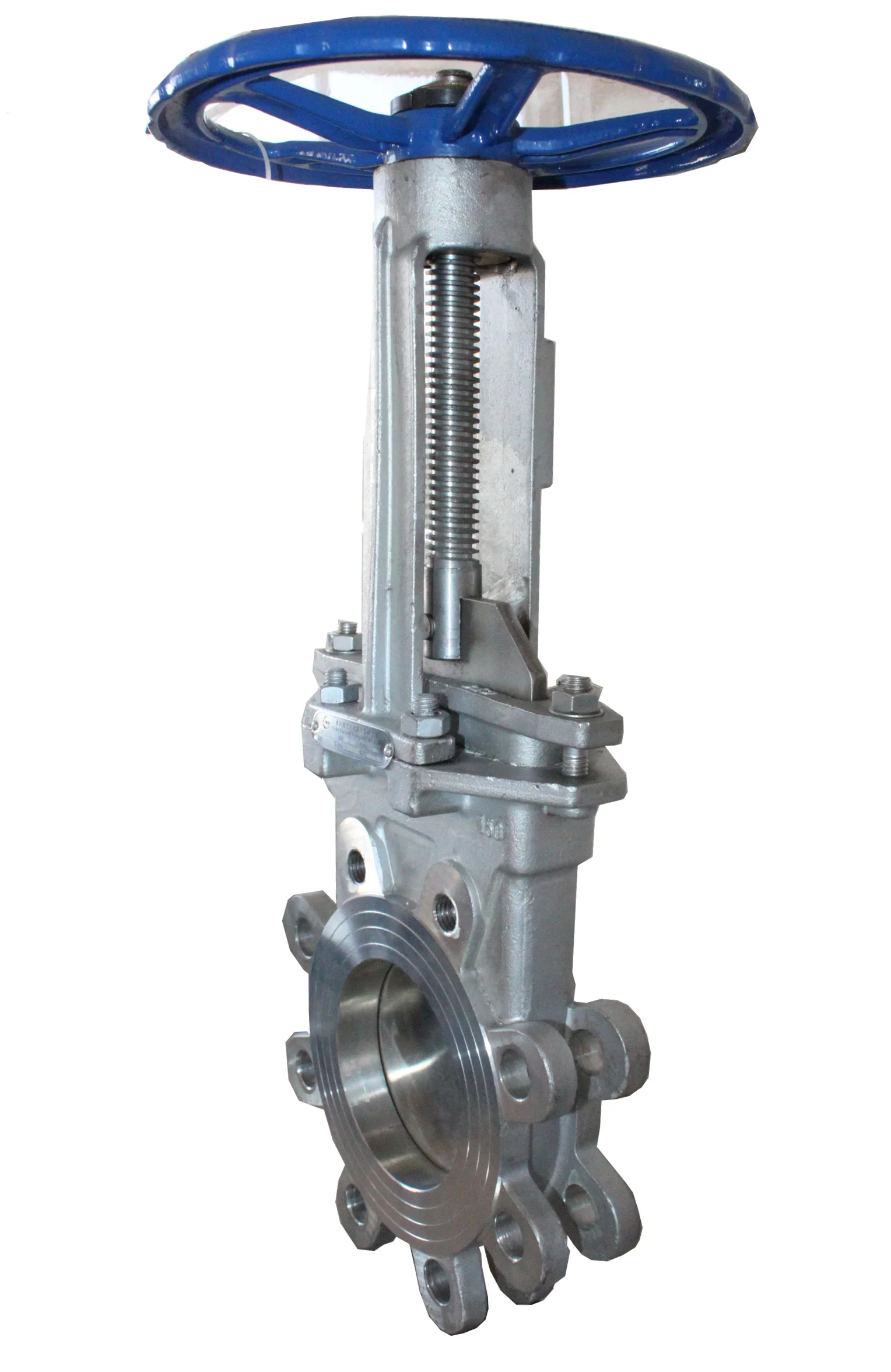

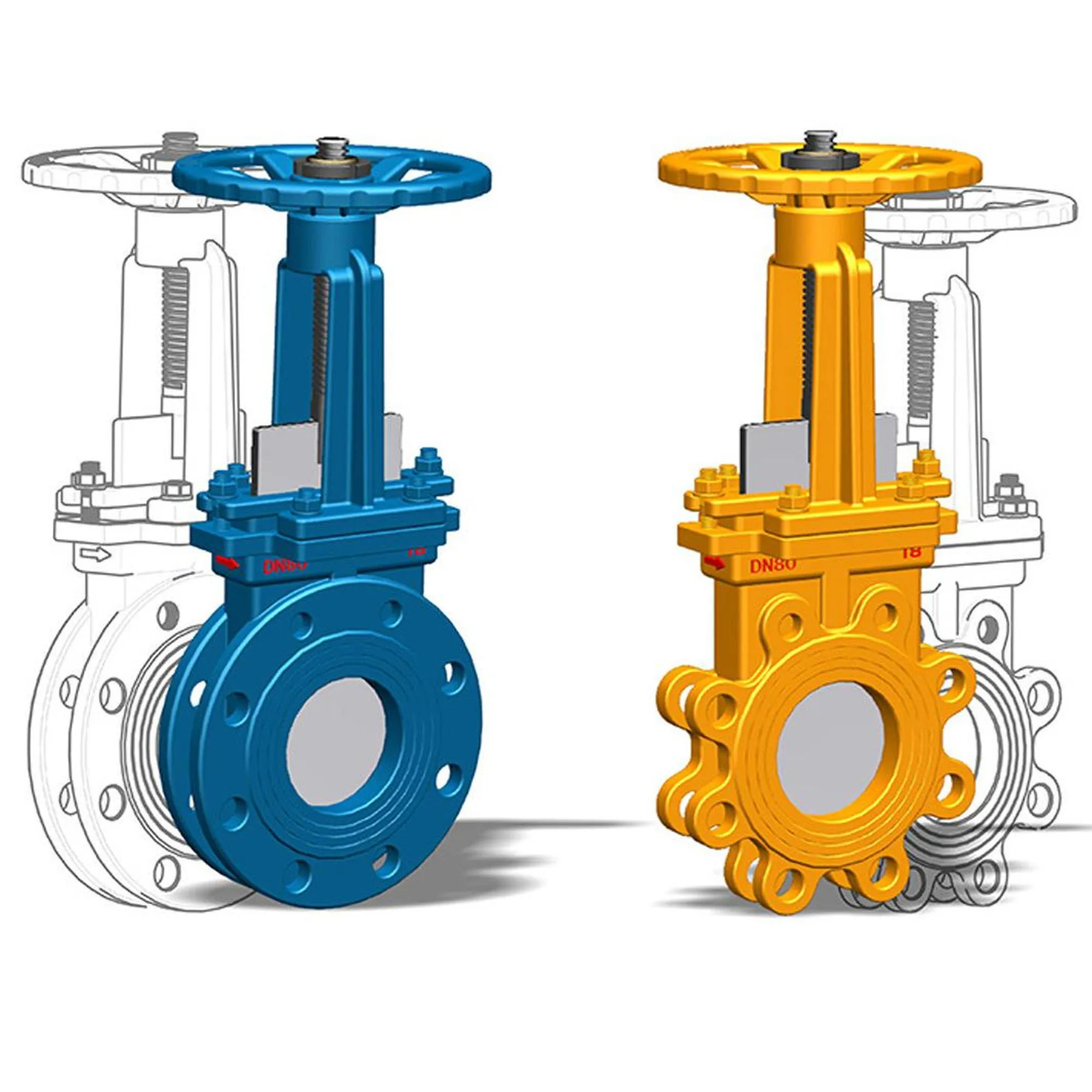

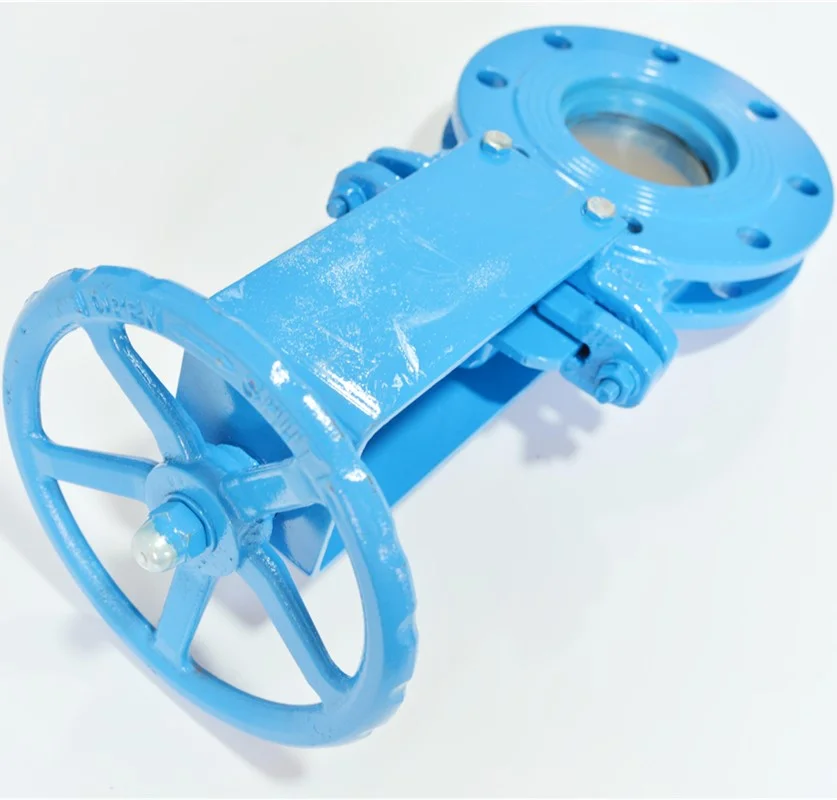

Pneumatic actuator knife gate valves are essential components in various industrial applications, known for their efficiency in controlling the flow of fluids. The primary feature of these valves is their unique design, which includes a sharp-edged gate that easily cuts through suspended solids, making them particularly effective in handling slurries and thick fluids. This design minimizes turbulence and allows for a more consistent flow, which is critical in processes requiring precision. The actuation mechanism utilizes compressed air, providing rapid opening and closing capabilities. This ensures quick response times within industrial systems, enhancing operational efficiency.

The advantages of pneumatic knife edge gate valves extend beyond mere functionality. Their durability is another key aspect; they are built to withstand harsh environments, featuring materials that resist corrosion and wear. They require minimal maintenance due to their simple construction leading to lower operational costs over time. Additionally, the pneumatic actuation minimizes the risk of leakage compared to traditional manual valves, thereby improving safety measures within facilities.

Furthermore, these valves can be easily integrated with automated control systems, contributing to advancements in process automation. The flexibility in design allows them to fit into existing pipelines without significant alterations. This adaptability coupled with their performance benefits solidifies pneumatic knife gate valves as a preferred choice among manufacturers and engineers in Sharjah and beyond for various heavy-duty applications.

Applications of Pneumatic Knife Edge Gate Valves in Industry

Pneumatic knife edge gate valves are integral in various industrial sectors, ensuring efficient and reliable control of fluid flow. Their primary applications include working with slurries and thick fluids, where traditional valves may fail due to clogging. The sharp edge design allows for effective shedding of accumulated solids, making them ideal for mining, wastewater treatment, and pulp and paper industries.

In the chemical processing sector, these valves handle corrosive materials, offering durability and resistance to wear. Their pneumatic actuator feature facilitates quick operation with minimal manual intervention, enhancing efficiency in production lines. Additionally, their ability to operate in high-pressure settings with varying temperatures underscores their versatility across diverse applications.

The table below outlines some specific uses of pneumatic knife edge gate valves across different industries:

Industry | Application | Benefits |

|---|---|---|

Mining | Control of slurry flows | Reduces clogging issues |

Wastewater Treatment | Isolation of channels during maintenance | Prevents backflow |

Pulp and Paper | Handling thick stock | Increased flow rate and reduced downtime |

Chemical Processing | Managing corrosive substances | Enhanced durability |

Food Processing | Isolation during cleaning processes | Compliance with food safety standards |

"Efficiency in fluid control is essential for maximizing production timelines."

The adaptability of pneumatic knife gate valves makes them crucial components across sectors requiring precise flow management and superior performance under challenging conditions. These features drive their increasing adoption among manufacturers seeking reliability in valve operations.

Choosing the Right Pneumatic Knife Gate Valve Manufacturer in Sharjah

Selecting a suitable manufacturer for pneumatic knife gate valves in Sharjah requires careful consideration of several key factors. Quality assurance plays a crucial role; potential manufacturers should adhere to stringent quality standards and certifications. Investigating the materials used in production reveals insights into durability and reliability, particularly in demanding industrial environments.

The range of pneumatic actuator knife gate valves offered is another important aspect. A versatile product line indicates the manufacturer's ability to cater to various applications. Inquire about their experience across different sectors; manufacturers with a diverse portfolio generally possess valuable insights into industry-specific needs.

Customer service and support further distinguish a competent manufacturer. Responsive and knowledgeable support can address operational queries, enhance installation processes, and ensure efficient maintenance. Additionally, seeking customer feedback and testimonials offers vital perspectives on performance and service quality.

Evaluating the manufacturer’s commitment to innovation is essential as well. Companies investing in research and development often produce more advanced products, which can lead to improved efficiency in applications utilizing pneumatic knife edge gate valves.

By focusing on these core aspects—quality assurance, product range, customer service, and commitment to innovation—industries can make an informed decision when selecting the right pneumatic knife gate valve manufacturer in Sharjah, ensuring optimal performance for their applications.

Comparative Analysis of Pneumatic Knife Gate Valves and Their Alternatives

Pneumatic knife gate valves are distinguished by their ability to provide effective isolation in various applications, particularly in the handling of slurries, solids, and viscous fluids. The pneumatic actuator mechanism ensures rapid operation and precise control, which contributes to operational efficiency. In contrast, traditional gate valves often face limitations regarding flow control and are less effective in managing high-solid content. Moreover, when comparing pneumatic knife edge gate valves with alternative shut-off options such as ball valves or butterfly valves, several factors come to the forefront.

The design of pneumatic knife gate valves, with their sharp-edged blade configuration, enables better shearing action and minimizes material buildup within the valve body. This characteristic significantly reduces maintenance requirements compared to alternatives that may trap debris or solids. Additionally, pneumatic operation offers the advantage of automation integration into existing systems for enhanced operational efficiency.

When analyzing the performance characteristics of these valves versus alternatives in environments demanding precision and reliability, pneumatic knife gate valves consistently outperform due to their ability to handle variable pressures and complex flow regimes with ease. The choice between these valve types ultimately hinges on specific application requirements, operational conditions, and desired performance outcomes within various industrial sectors in Sharjah. Understanding these nuances aids in making informed procurement decisions that align with operational goals and long-term reliability needs.

Conclusion

The significance of pneumatic knife gate valves in the industrial landscape is underscored by their robust performance and versatile applications. Their design enhances the efficiency of fluid control in various systems, particularly in demanding environments such as mining, wastewater treatment, and power generation. The integration of pneumatic actuators with these valves offers precise control, promoting operational safety and reliability. Investing in quality products from reputable pneumatic knife gate valve manufacturers in Sharjah ensures long-term benefits such as reduced maintenance costs and prolonged service life. Thorough knowledge of the specifications and advantages of different models empowers organizations to make informed decisions tailored to their unique operational needs, allowing for the optimization of processes across diverse sectors. Understanding the competitive landscape in Sharjah can further aid in identifying the right solutions for effective fluid management systems.

FAQs

What is a pneumatic actuator knife gate valve?

A pneumatic actuator knife gate valve is a type of valve that utilizes compressed air to operate its opening and closing mechanism. This design allows for efficient control of fluid flow in various industrial applications.

What are the benefits of using pneumatic knife edge gate valves?

Pneumatic knife edge gate valves offer several advantages including rapid open and close operations, low maintenance requirements, and reliable sealing capabilities. These features make them suitable for handling slurries, solids, and other challenging materials.

Where can I find pneumatic knife gate valve manufacturers in Sharjah?

Sharjah is home to various manufacturers specializing in pneumatic knife gate valves. A detailed search can pinpoint reliable suppliers known for high-quality products and customer support.

What applications are suited for pneumatic knife gate valves?

These valves are commonly used in industries such as wastewater treatment, mining, food processing, and power generation. They excel in managing flow control where the handling of thick slurry or solid materials is necessary.

How do I choose the right manufacturer for pneumatic knife gate valves?

Selecting a manufacturer involves assessing their reputation, product range, certification standards, and customer service. Recommendations from industry peers also provide valuable insights into potential partners.

What differentiates pneumatic knife gate valves from other valve types?

Compared to traditional valves like ball or globe types, pneumatic knife gate valves feature a streamlined design that allows them to cut through viscous materials with ease. This functionality sets them apart when handling challenging substances.

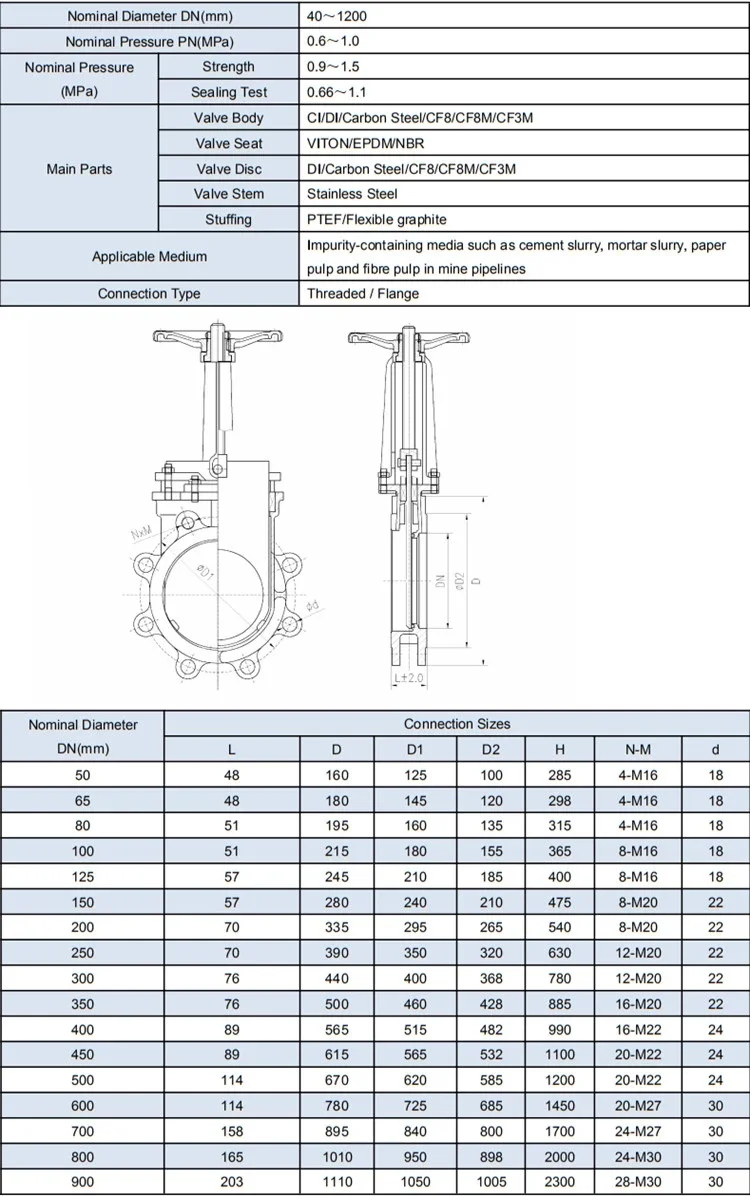

| Application | General | Place of Origin | shenzhen, China |

|---|---|---|---|

| Power | Manual,Pneumatic,Electric | Customized support | OEM, ODM |

| Warranty | 2 year | Model Number | Knife Gate Valve |

| Temperature of Media | Medium Temperature, Normal Temperature | Brand Name | JRVAL |

| Media | water,oil,gas,Slurry | Standard or Nonstandard | Standard |

| Product name | knife gate valve stainless steel india | Name | pneumatic knife gate valve dn 800 |

| Type | knife gate valve | Certificate | ISO9001 |

| Working pressure | PN10/PN16 | Working Temperature | 20 -120 |

| MOQ | 1 Piece | Service | Trade Assurance |

| OEM | OEM Service |

1. The lifting gate sealing surface can scrape off the adhesion on the sealing surface and automatically clean up the debris.

2.Stainless steel gate can prevent seal leakage caused by corrosion.

3. Hard all-gold sealing surface can ensure the sealing wear

resistance and requirements.

Q:Are you trading company or manufacture?

A:We are factory located in shenzhen,China.

Q:What's your product range?

A:We specialize in knife gate valves and steam traps.

Q:Do you provide sample?Is it free or extra?

A:Yes,we could offer the sample for free charge but do not pay the cost of the freight.

Q:How long is your deliver time?

A: generally it is 10 days if the goods are in stock or it is 35 days if the goods are not is stock, it is according quantity.

Q:How do your factory do regarding quality control?

A: quality is priority,JR people always attaches great importance to quality controlling from the every beginning to the end.

Q:Could you offer OEM service?

A:Yes OEM is OK!